WE-67K 63T2500 HK58T 4+1 Axis CNC Electro Hydraulic Press Brake Machine

Product Details

Place of Origin: China

Brand Name: AOXUANZG

Certification: CE

Model Number: WE67K-63T2500

Payment & Shipping Terms

Minimum Order Quantity: 1 Set

Packaging Details: Standard export packing

Delivery time: 30 days

Payment Terms: L/C, T/T, Western Union, MoneyGram

Supply Ability:120 sets/Year

Category: CNC Electro-hydraulic Press Brake

Tags: CNC Electro-hydraulic Press Brake CNC Hydryaulic Press Brake Machine Hydraulic Bending Machine Press Brake Machine pressbrakebender.hydraulicpressbrake

Brand: AOXUANZG

Description

.

Main Features:

1.Special numeric-control system is fitted with mainframe of the bending machine.

2.Multi-work-stop programming function is able to achieve an automatic operation and continues positing of multi-step procedures,as well as an automatic precision adjustment for positions of rear stopper and gliding block.

3.The machine is provided with bend counting function, for a real-time display of processing quantity and power-failure memory of

positions of stopper and gliding block, as well prccedures and paremeters.

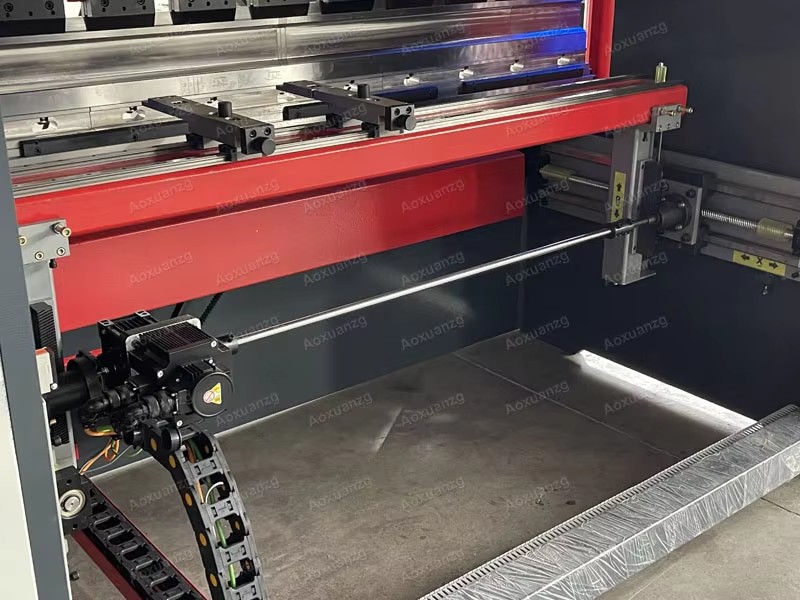

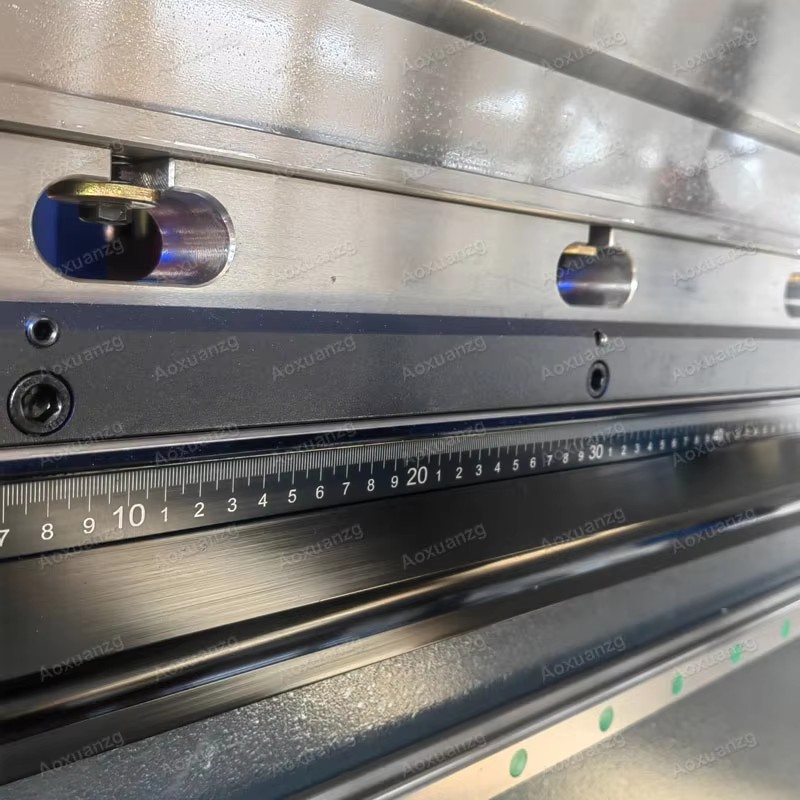

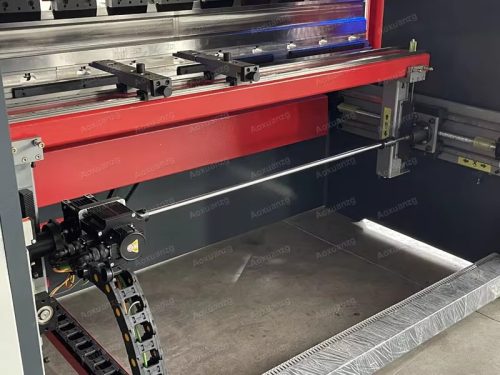

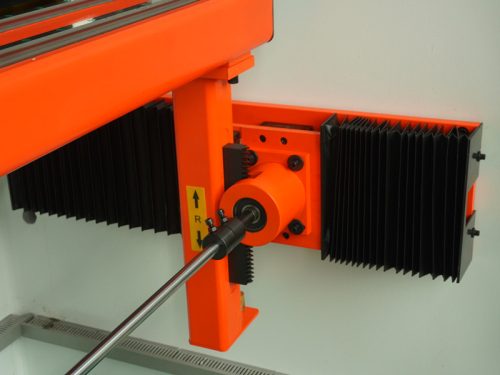

4.Imported ball bearing lead screw and linear guide rail are used for rear stopper, to ensure the positioning precision of rear stopper, for processing precision of machine to be higher.

The standard cofiguration:

1. HK58T controller system

2. Germany Rexroth valve group

3. Italian GIVI grating ruler

4.Pipe joint Germany

5.Siemens Motors, Germany

6. Sunny oil pump, the US

7. Servo motor Nanjing Tuco

8. Ball screw linear guide, Tawan(China)

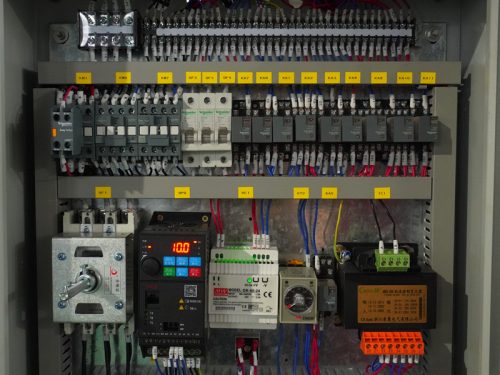

9. Schneider Electric System, France

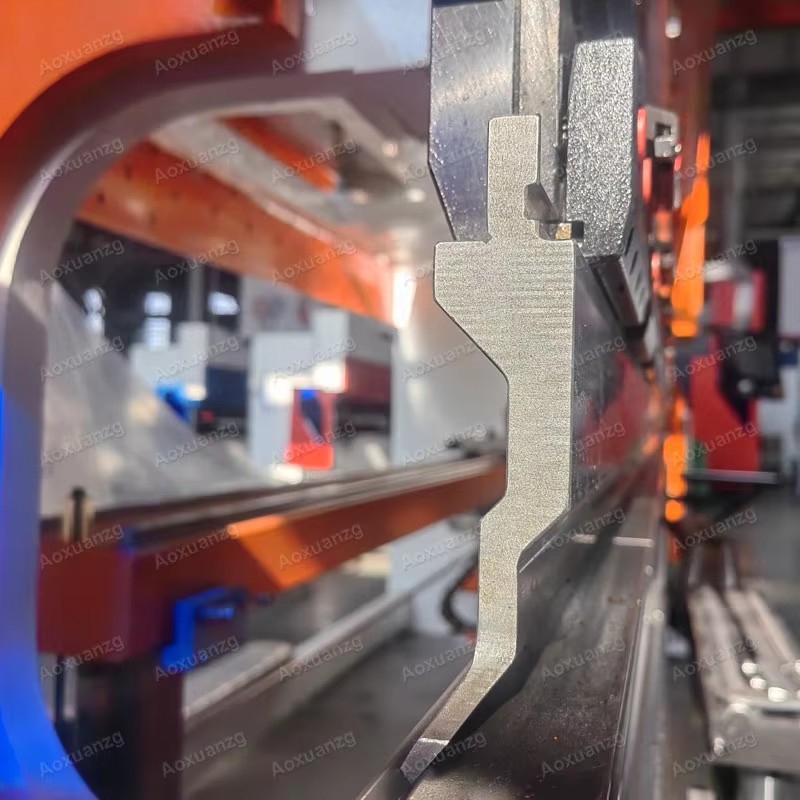

10. a set of mold for free (if you want a customized mold, just tell us, we can customized them for you.)

11.Some quick clips

12. Front support

13.High accuracy backguage

14. Side guardrail and rear guardrail

15. Light curtain protection and Laser protection (Charged extrally)

16. Foot switch

17. Or can be customized by your requirements

Configure Image

HK58T Controller Introduction:

HK58T Controller System : Electro-Hydraulic servo CNC system

3D animation bending Automatic sorting bending CAD drawing import Pressure: 501 18.5-inch full-color touch screen Function introduction

01.Support angle programming and depth programming switching

02.Support mold library product library setting

03.Each step can freely set the opening height

04.The speed change point position can be freely controlled

05.Standard Y1, Y2, R and other multi-axis extensions

06.Support mechanical compensation workbench control

07.Support Support large arc automatic program generation

08. Support multiple step-changing options such as top dead point, bottom dead point, loose foot, delay, etc., effectively improving processing efficiency

09. Support simple electromagnet bridge

10. Support fully automatic pneumatic drag bridge function

11. Support automatic bending, realize unmanned bending control, and support up to 25 steps of automatic bending

12. Support valve group configuration function, fast down, slow down, return, unloading action and valve action time control

13. 200 product libraries 25 steps, each product library name is customized in Chinese and English, large arc supports 99 steps

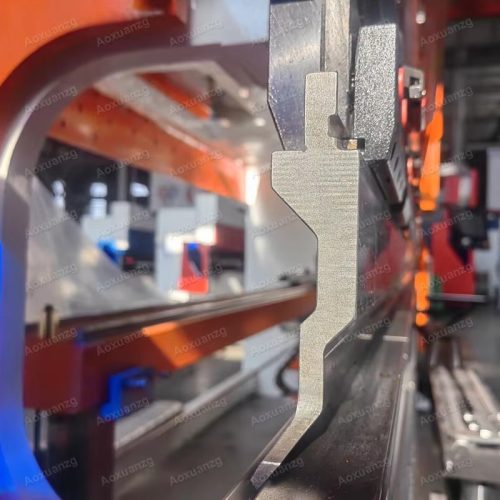

Customized Molds:

Standard Moulds:

Machine Tetail picture:

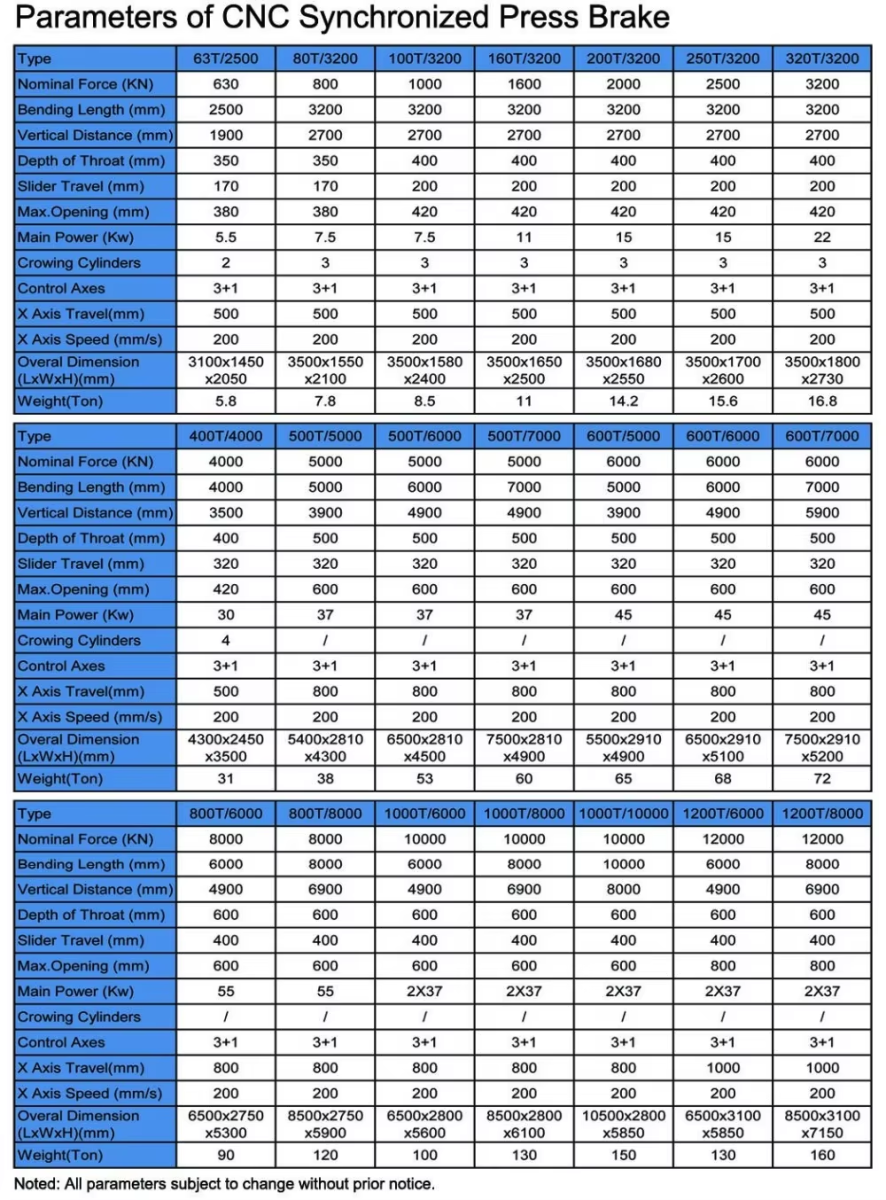

Parameter:

Certificate:

Pre-sales.

* Project design, performance introduction, technical agreement, contract signing, packaging

* Inquiry and consulting support.

* Sample testing support.

In-sales.

* We will provide you with the latest progress in the product assembly, packaging and transportation.

After-sale.

* We will provide free accessories for the damage to non – human parts.

*The support package includes training such as machine installation guidance, as well as video-based operational training, and other related services.

* And our technical staff can go abroad to provide technical guidance.

Packing&Shipping

Customer: