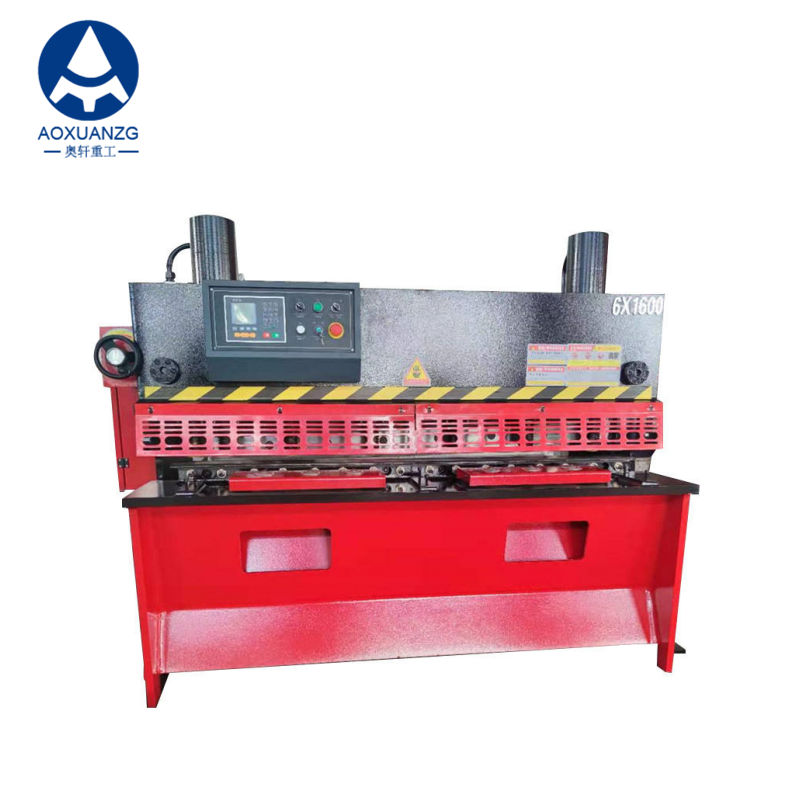

High Accuracy Automatic QC12K 6mmx1600mm CNC Hydraulic Shearing cutting Machine With E21S

Product Details

Place of Origin: China

Brand Name: AOXUANZG

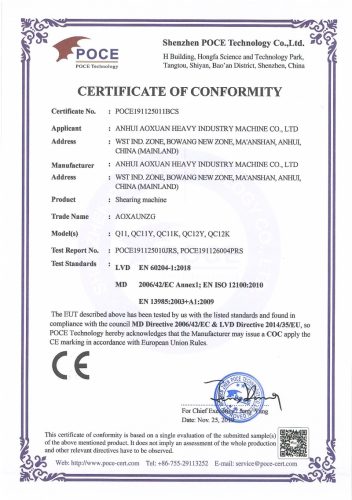

Certification: CE

Model Number: QC11Y-6X3200

Payment & Shipping Terms

Minimum Order Quantity: 1 Set

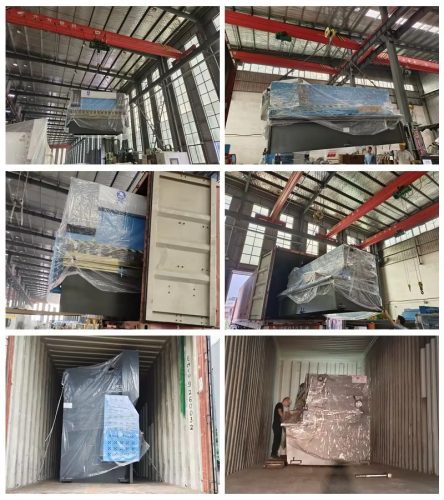

Packaging Details: Standard export packing

Delivery time: 30 days

Payment Terms: L/C, T/T, Western Union, MoneyGram

Supply Ability: 50 sets/Year

Category: Hydraulic Guillotine Shearing Machine

Tags: CNC hydraulic cutting machine E21s hydraulic cutter guillotine shearing machine metal steel plate cutting machine

Brand: AOXUANZG

Description

Introduce:

Hydraulic sheet metal cutting machine is a frequently used shearing machine in metal processing industry. Owing to its outstanding productivity and low noise, hydraulic guillotine is increasingly used by metal fabricating industries. In addition, CNC system ensure easy operation and adjustment.

Main Features:

1.Totally EU streamlined design, monoblock by welding robots & aparatus and stress relief process by annealing treatment.

2. Our engineers utilize parametric 3D SolidWorks using FEM & DOE analysis as well as static and mechanism analysis.

3. Our Hydraulic Shearing Machine is a swing beam action machine which is produced in a variety of cutting lengths and capacity options.

4. Adopt integrated hydraulic system, more reliable and easy for maintenance. And the hydraulic system from Bosch-Rexroth, Germany.

5. Equipped with lighting-alignment, so as to align when shearing. The stroke of knife beam can be adjusted in stepless mode.

6. Hydraulic drive, return of knife beam is smooth and prompt by nitrogen cylinder.

7. CE conformity including tiltable front finger guard and optical rear safety guard.

8. Safe fence and the electric interlocker have been designed for the machine to ensure the

operation safety.

2. Our engineers utilize parametric 3D SolidWorks using FEM & DOE analysis as well as static and mechanism analysis.

3. Our Hydraulic Shearing Machine is a swing beam action machine which is produced in a variety of cutting lengths and capacity options.

4. Adopt integrated hydraulic system, more reliable and easy for maintenance. And the hydraulic system from Bosch-Rexroth, Germany.

5. Equipped with lighting-alignment, so as to align when shearing. The stroke of knife beam can be adjusted in stepless mode.

6. Hydraulic drive, return of knife beam is smooth and prompt by nitrogen cylinder.

7. CE conformity including tiltable front finger guard and optical rear safety guard.

8. Safe fence and the electric interlocker have been designed for the machine to ensure the

operation safety.

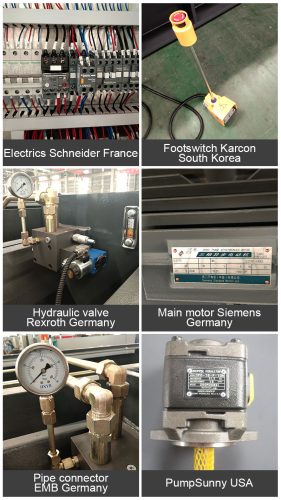

Equipment:

Estun E21S CNC control System

Powered Back gaugeX-axis

DELTA Inverter controlled back gauge

HIWIN Ball screws & Polished rod with 0,05mm accuracy

Squaring Arm and Front Support Arms

Germany Bosch-Rexroth Hydraulic

Germany EMB Tubing connector

Germany Siemens Main Motor

Schneider Electrics

Hydraulic &Electrical overload protection

Cutting Line illumination and wire for shadow line cutting

Top blade with four cutting edges and bottom blade with four cutting edges.(6CrW2Si)

E21S control system:

High-definition LIQUID crystal display screen, with Chinese and English two languages optional, one page display

programmingparameters, when writing programs more fast and convenient.

* Rear gear: intelligent positioning, or manual adjustment as required to remove the mechanical hand positioning device.

* Shear stroke: built-in shear time relay, simple operation, cost saving.

* Shearing Angle: The built-in shearing Angle adjustment function eliminates the Angle indicator light and the button.

* Blade gap: encoder feedback, timely display blade gap size, easy to operate.

* Through CE certification, to meet the needs of overseas markets.

Tetail picture:

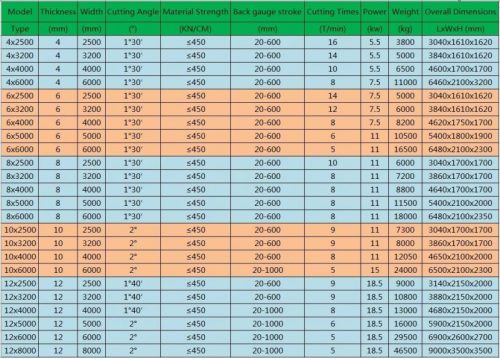

Parameter:

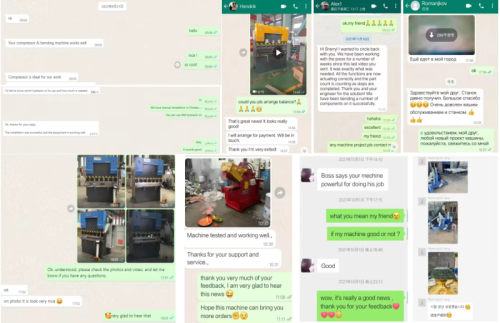

Customer praise:

Machine CE Certificate:

Our factory:

Packing and delivery:

Our service:

Pre-sales.

* Project design, performance introduction, technical agreement, contract signing, packaging

* Inquiry and consulting support.

* Sample testing support.

In-sales.

* We will provide you with the latest progress in the product assembly, packaging and transportation.

After-sale.

* We will provide free accessories for the damage to non – human parts.

* And our technical staff can go abroad to provide technical guidance.