APA-25T pneumatic punching machine with feeder and decolier production line

Product Details

Place of Origin: China

Brand Name: AOXUANZG

Certification: CE

Model Number: APA-25T

Payment & Shipping Terms

Minimum Order Quantity: 1 Set

Price: $10000-$13000/Set

Packaging Details: Standard export packing

Delivery time: 50-60 days

Payment Terms: L/C, T/T, Western Union, MoneyGram

Supply Ability: 50sets/Year

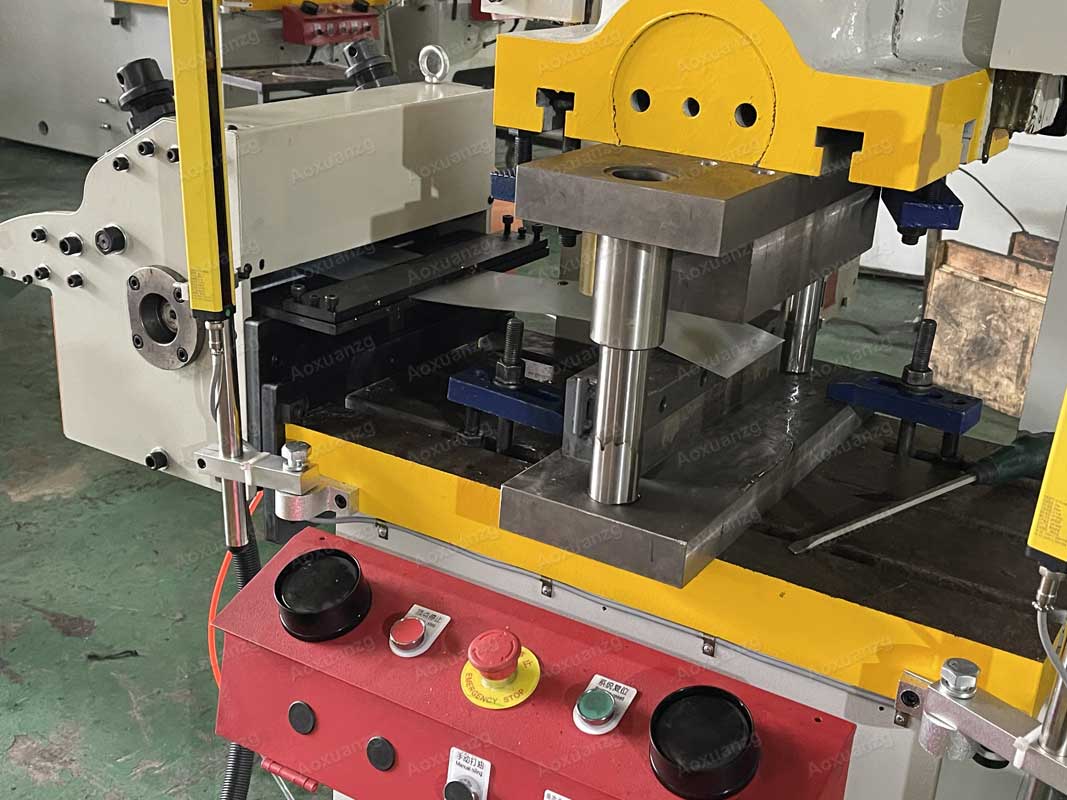

The main function of a pneumatic punch production line is to automate the high-speed, repetitive marking, perforating, or forming of materials using air-powered force.

While the overall goal is similar to other punch lines, the use of pneumatics defines its specific characteristics, advantages, and ideal applications.

Let’s break down this main function into its core aspects:

1. The Core Mechanism: Pneumatic Power

The defining feature is the use of a pneumatic punch press (or multiple presses in a line). This means:

-

Power Source: Compressed air.

-

Action: The air pressure drives a piston, which moves the punch down into the material and then retracts it.

-

Control: A PLC (Programmable Logic Controller), a sensor, or a foot pedal typically triggers the solenoid valves to control the action.

2. The “Production Line” Aspect

This isn’t just one machine; it’s a coordinated system. The main function integrates several processes:

-

Automated Feeding: The material (sheets, strips, or pre-formed parts) is automatically fed into the punch station. This can be a conveyor belt, a roller feeder, or a robotic arm.

-

Precise Positioning: Guides, clamps, or a CNC-controlled XY table accurately position the material under the punch head.

-

Punching Operation: The pneumatic press performs its task (e.g., punching a hole, stamping a logo, embossing).

-

Ejection/Collection: Mechanical mechanisms remove the finished part and separate the scrap material.

Advantages of the production line:

1. The material rack adopts a straightening and feeding integrated machine to save space, straighten raw materials, and achieve better product production effects;

2. The feeder adopts a servo system with automatic tension control.

3. The raw material position adjustment is simple, reducing the situation of debugging and wasting raw materials.

lass=”yoast-text-mark” />>4.PLC adopts intelligent model system, which can store 50 sets of mold specifications and mold adjustment data.

5.With the continuous upgrading design of machine and mold technology, production noise is greatly reduced.

6.Equipped with photoelectric protection operator.

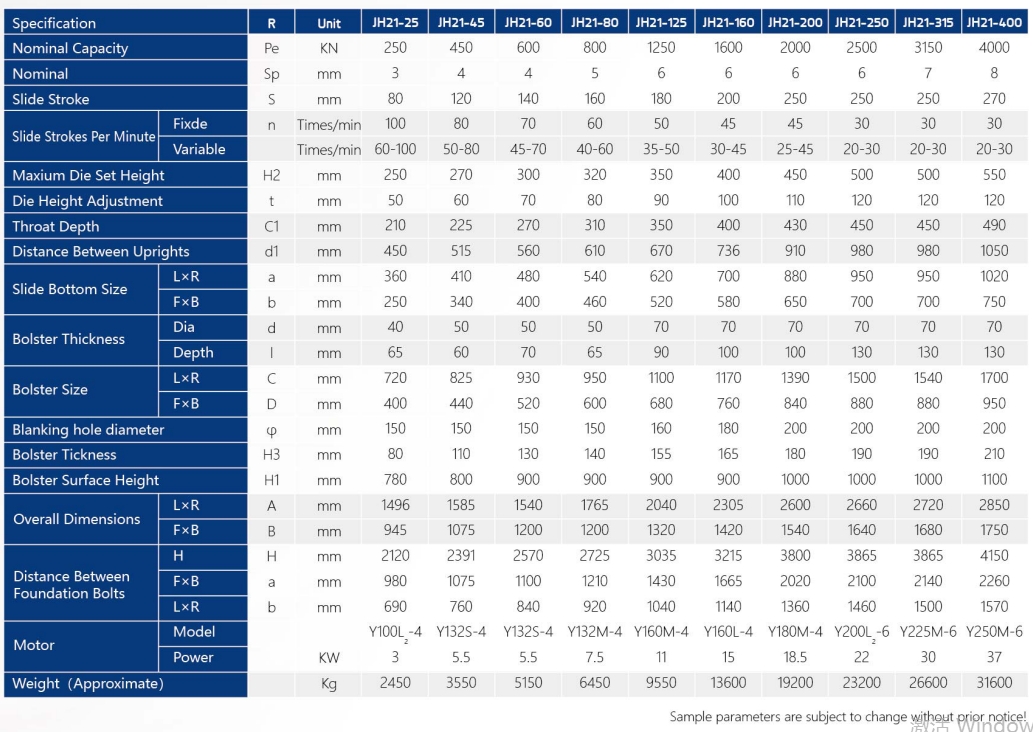

Parameter:

ight=”732″ />

ight=”732″ />

Name: Automatic punching line

Brand:Aoxuanzg ,China

We can supply the whole line, uncoiler, leveler, NC Feeder, Press machine. and test it in our factory.

Packing:

1. Before packaged, the machines will be tested strictly to guarantee the stability and high accuracy.

2. After tested, the machines will be wrapped with plastic sheet ,

3,a,Small size : carefully packed in wooden cases ;

b,Big size: machine will be securely wired into the container by steel wire.

For more information, please contact me ~*^-^*