Two Cavities Aluminum Foil Lunch Containers Semi Automatic Production Line

$23,000.00

Product Details

Place of Origin: China

Brand Name: AOXUANZG

Certification: CE

Model Number: JF21-45

Payment & Shipping Terms

Minimum Order Quantity: 1 Set

Price: $23000-$50000/Set

Packaging Details: Standard export packing

Delivery time: 50-60 days

Payment Terms: L/C, T/T, Western Union, MoneyGram

Supply Ability: 50sets/Year

Product introduction:

An Overview of the Automatic Aluminum Foil Lunch Box Production Line

This integrated system combines precision engineering with automated efficiency to meet diverse manufacturing needs.

1. Core System Components

The production line integrates multiple coordinated subsystems, starting with an oil tank-equipped automatic feeding system. The material then moves to a high-precision pneumatic punch and customized multi-cavity mold for forming. Afterwards, a multi-track stacker organizes finished products while a synchronized waste system handles scrap material.

2. Key Operational Advantages

The integrated design ensures high precision, efficiency, and minimal waste. As a result, it has become the preferred choice for SMEs seeking a reliable and cost-effective production solution.

3. Production Versatility & Capabilities

The line is capable of manufacturing a range of aluminum foil products, from multi-cavity lunch boxes to coffee capsules.

Semi Automatic Components:

1. Automatic feeder.

2. 45/63/80T Aoxuanzg brand pneumatic press machine.

3. Single cavity / 2-cavity/3 cavity … Moulds.

4, Air compressor.

Technical Features & Advantages

-

Our servo-controlled feeder automatically maintains proper tension to ensure reliable handling of delicate materials.

-

Operators can easily adjust the foil positioning and minimizing material waste during setup.

-

The optimized oil tank design cuts fuel consumption to 5 liters per ton and reduce operating costs significantly.

-

Simple programming enables quick stacker adjustments, allowing minimal staffing for full-line operation.

-

The intelligent PLC system stores 50 mold profiles for fast changeovers.

-

We continuously upgrade our machines and molds, achieving quieter production environments

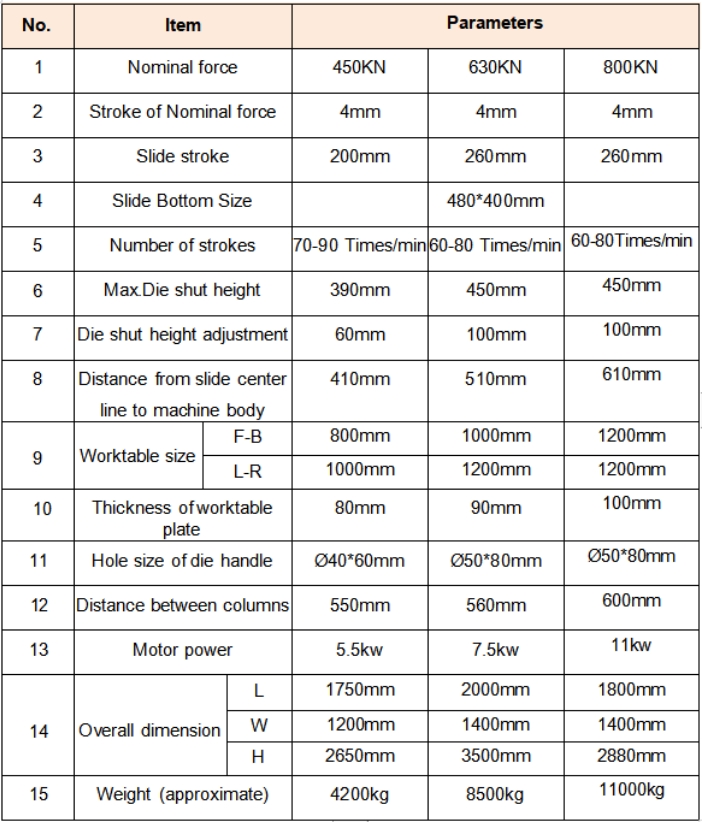

Parameter:

Molds:

1. The moulds that we design and produce are suitable for every kind of machine or press.

2. We produce mould with the best quality steel in China. And some main mould areas are made high-temperature heat treatment for proper hardness, which ensure moulds are in top quality and long life.

3.To meet diverse customer requirements, we design and manufacture molds in various rim specifications.

4. We can design and produce the mould in multi-cavities, 1, 2, 3, 4 cavities or more. no matter it is one compartment container or multi-compartments container.

5. We can print your preferred logos upon request.

6. Scientific design make the Cutting Scrap Rate under good control.

7. Container shapes: square, rectangular, circular, oval, special shapes etc.

Packing:

1. All machines undergo rigorous pre-shipment testing to ensure consistent stability and precision. This comprehensive verification process guarantees reliable performance in all production environments.

2. After tested, the machines will be wrapped with plastic sheet ,

3,a,Small size : carefully packed in wooden cases ;

b,Big size: machine will be securely wired into the container by steel wire.

For more information, please contact me ~*^-^*