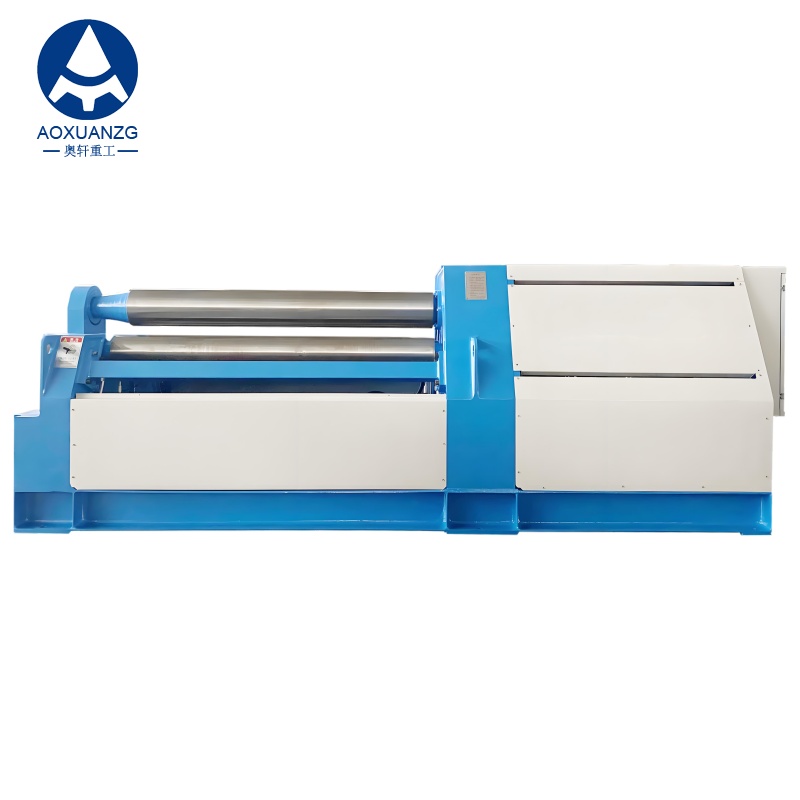

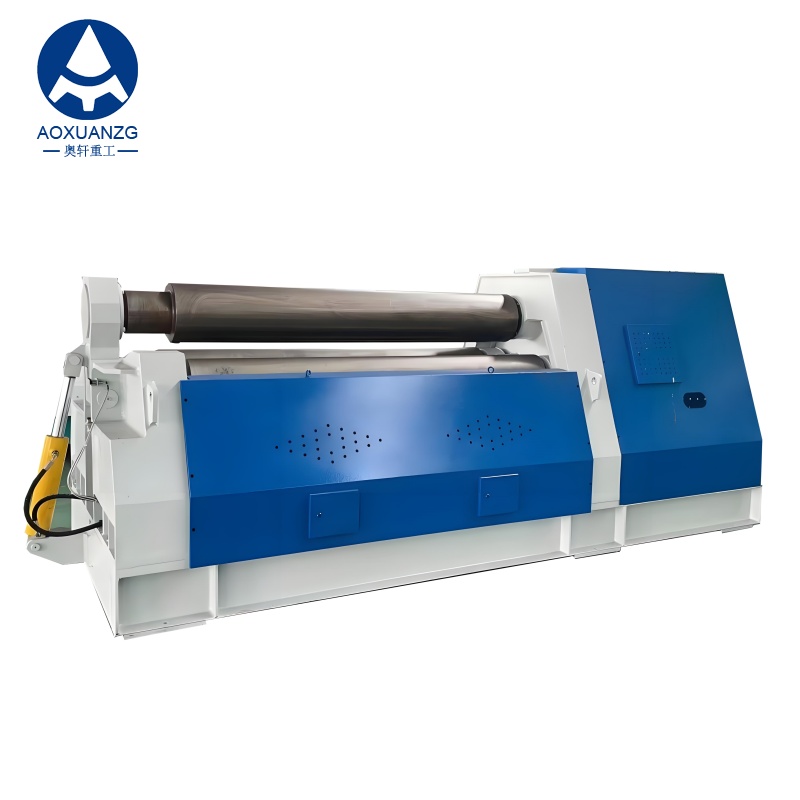

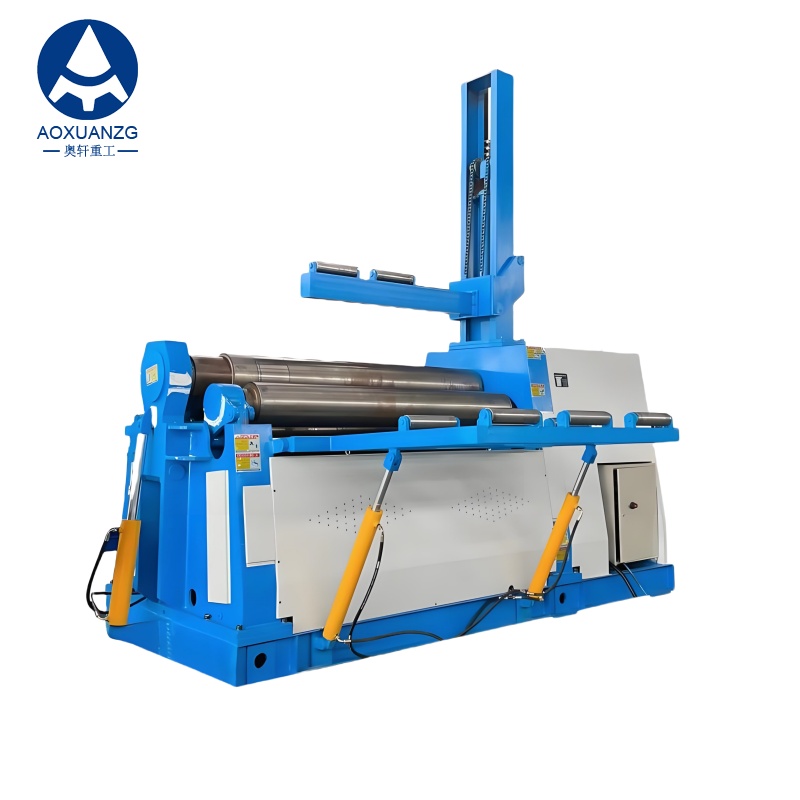

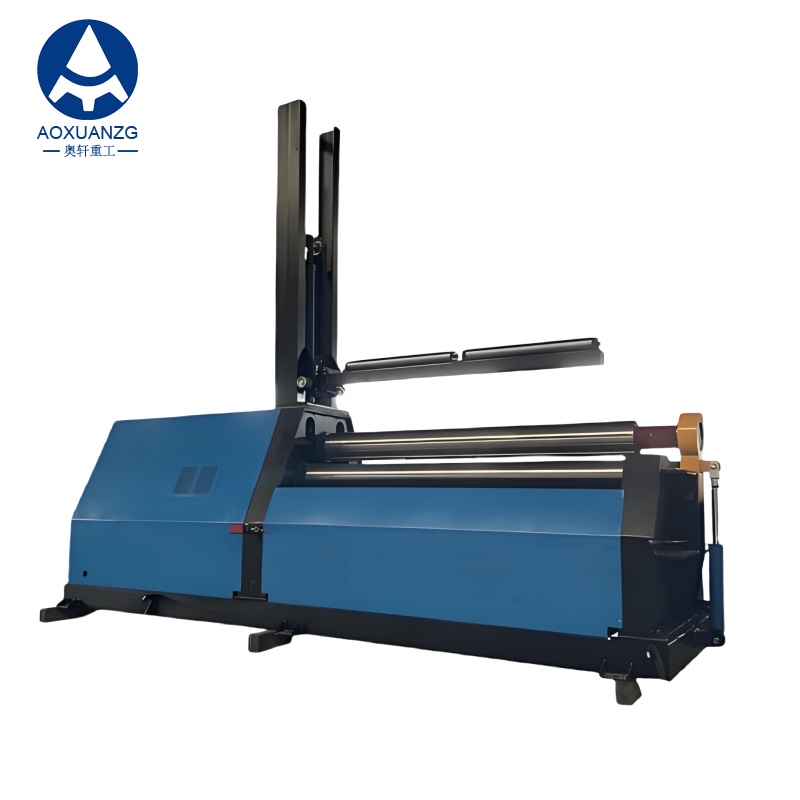

Dobladora hidráulica de placas de acero de 6000 mm, con cuatro rodillos y tres rodillos, con rodillo cónico.

1. Precio FOB de Shanghái, China

2、Precio válido: dentro de 30 días;

3、Método de pago: Cuando se firman el contrato de venta del producto y el acuerdo técnico, se pagará 30% del monto total del contrato y 70% del monto total del contrato se pagará en el momento de la entrega mediante T/T o L/C.

4、Período de entrega: 30 días hábiles después de recibir el depósito;

5、Embalaje: embalaje simple, no reciclable;

Dobladora hidráulica de placas de acero de 6000 mm, con cuatro rodillos y tres rodillos, con rodillo cónico.

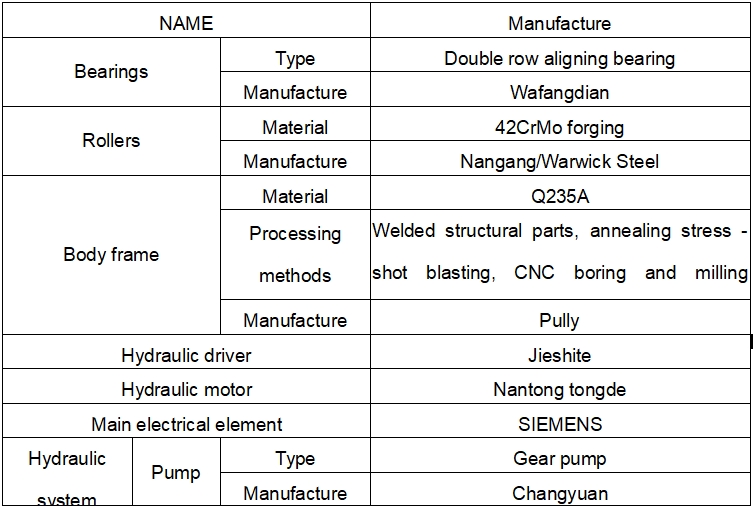

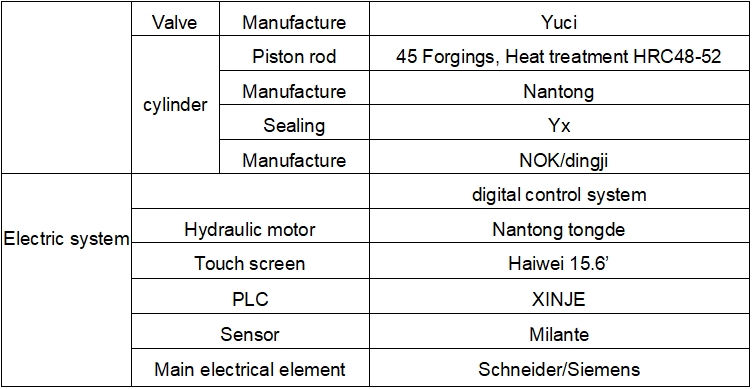

Características de la máquina laminadora de placas hidráulica de cuatro rodillos CNC

Esta máquina está diseñada para una alta eficiencia, permitiendo el precurvado de ambos extremos de la placa y el laminado completo de un cilindro en una sola configuración sin invertir la pieza de trabajo.

Su mecanismo de accionamiento principal es el rodillo superior. Los rodillos inferior y laterales se accionan hidráulicamente para un ajuste vertical preciso. La potencia se transmite a la placa mediante fricción, mientras que un rodamiento central soporta el rodillo inferior para garantizar la rigidez y evitar la deflexión.

Ventajas clave:

-

Accionamiento de alta eficiencia: Utiliza cojinetes de rodillos autoalineables similares a los de los rodillos de trabajo del molino, lo que da como resultado baja fricción, mínima pérdida de potencia, larga vida útil y menor consumo de energía.

-

Control CNC de precisión: El movimiento sincronizado de los rodillos inferiores y laterales se gestiona automáticamente mediante un avanzado sistema CNC. Esto garantiza una alta precisión en los cilindros y conos de laminación, con control automático de los parámetros de inclinación y avance.

-

Sistema de control avanzado: Equipado con un sistema CNC nacional líder con pantalla visual. Admite cálculos fundamentales de laminación, control de procesos, almacenamiento de parámetros, protección de software, alarmas de fallos y un diálogo intuitivo entre el operador y la máquina.

Esta máquina es una laminadora de placas de cuatro rodillos. Su principio de funcionamiento consiste en el movimiento coordinado de cuatro rodillos:

-

Rodillo superior: Actúa como motor principal, girando para arrastrar la placa.

-

Rodillo inferior: Se mueve verticalmente para sujetar la placa y generar la fricción de alimentación necesaria.

-

Rodillos laterales: Ajuste hacia arriba y hacia abajo en un ángulo con respecto al eje vertical, aplicando fuerza precisa para doblar la placa a la curvatura deseada.

La principal ventaja de esta configuración es su capacidad para ajustar los rodillos laterales tanto para doblado simétrico como asimétrico. Este proceso minimiza los extremos planos sin doblar en los bordes de entrada y salida de la placa. Por consiguiente, a diferencia de las máquinas de tres rodillos, elimina la necesidad de una operación de predoblado independiente y de equipos dedicados, a la vez que proporciona una función de nivelación aproximada.

Estas eficiencias lo hacen ideal para sectores críticos como el petróleo, la química, la fabricación de calderas, la construcción naval, la energía hidroeléctrica, las estructuras metálicas y las industrias de maquinaria.

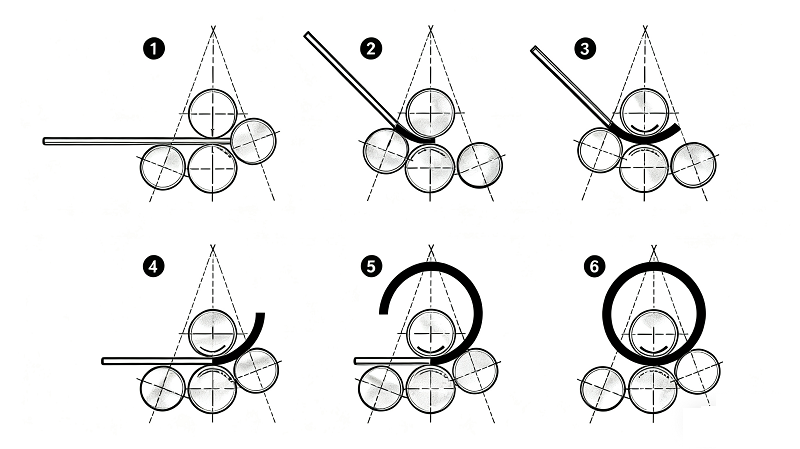

Proceso de doblado de placas

-

Procedimiento estándar de laminado de placas

-

Posición y abrazadera: Alinee el borde delantero de la placa con el rodillo principal delantero. Levante el rodillo inferior para sujetar la placa firmemente.

-

Conjunto para precurvado: Retraiga la placa de modo que su borde delantero quede cerca del punto de contacto de los rodillos superior e inferior. Baje el rodillo frontal y suba el rodillo posterior a sus posiciones de precurvado.

-

Pre-doblar el borde: Accione los rodillos principales para girar la placa. Predoble el borde delantero a la curvatura requerida.

-

Listo para rodar: Baje el rodillo lateral trasero y levante el rodillo lateral delantero a sus posiciones iniciales para el ciclo de laminación completo.

-

Haz rodar el plato: Accionar los rodillos principales para enrollar continuamente la placa formando un cilindro.

-

Terminar el rollo: Una vez que el borde posterior de la placa se acerca al punto de contacto, detenga la rotación para completar el proceso de laminado.

-

¿Por qué elegir nuestra máquina dobladora de cuatro rodillos?

-

Ahorro sustancial de energía: Un sistema de accionamiento hidráulico de alta eficiencia reduce el consumo de energía en un 40% en comparación con las máquinas convencionales.

-

Funcionamiento sin mantenimiento: La tecnología de lubricación permanente garantiza que los rodamientos no requieran mantenimiento durante toda su vida útil, ahorrando tiempo y costos.

-

Máxima productividad: La presión de sujeción ajustable elimina el deslizamiento, lo que aumenta su producción en un 50-80% en comparación con los modelos de tres rodillos.

-

Flexibilidad excepcional: Consiga curvas más cerradas y forme cilindros con diámetros de hasta sólo 1,1 veces el tamaño del rodillo superior.

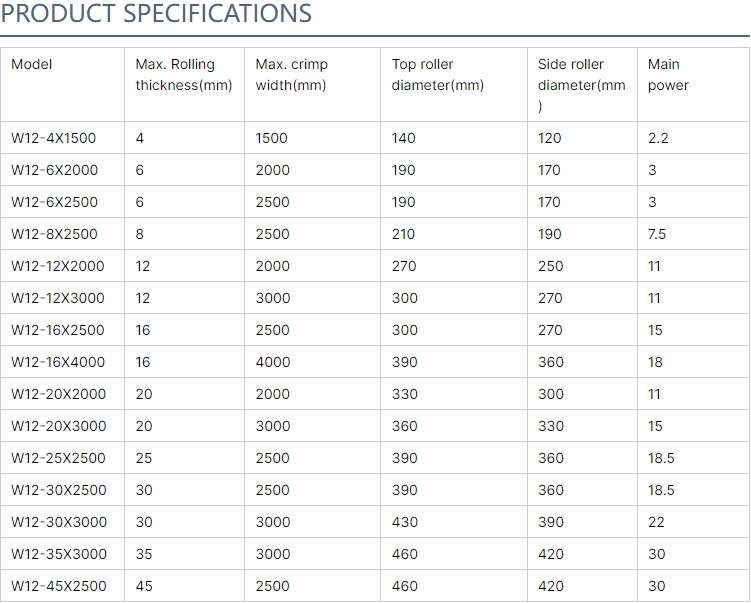

Parámetros de la máquina

Características técnicas del sistema de control

-

Arquitectura central: Incluye un PLC industrial de alta confiabilidad y codificadores rotatorios, formando un sistema de control estable y de alto rendimiento.

-

Capacidades del CNC: Proporciona monitoreo en tiempo real, transferencia de datos sin interrupciones y una función de memoria de apagado para conservar las configuraciones.

-

Sincronización de precisión: El PLC controla automáticamente los rodillos inferiores y laterales, garantizando una precisión de sincronización de ±0,15 mm.

-

Interfaz hombre-máquina (HMI): Una pantalla programable muestra las posiciones de los rodillos en tiempo real y permite la configuración de parámetros.

-

Detección de alta precisión: Los transductores de desplazamiento ofrecen una resolución de 0,10 mm y una precisión de visualización de ±0,10 mm.

-

Funcionalidad inteligente: Equipado con una función automática de autodiagnóstico y evaluación.

Configuraciones de la máquina laminadora hidráulica de cuatro rodillos