125T high CNC high precsion pneumatic punching machine

1、Price content FOB Shanghaiprice , China

2、Valid price: within 30 days;

3、Payment method: When the product sales contract and technical agreement are signed, 30% of the total amount of the contract will be paid, and 70% of the total amount of the contract will be paid at the time of delivery by T/T or L/C.

4、Delivery period: 30 working days after receipt the deposit;

5、Packing: simple packaging, not recycling;

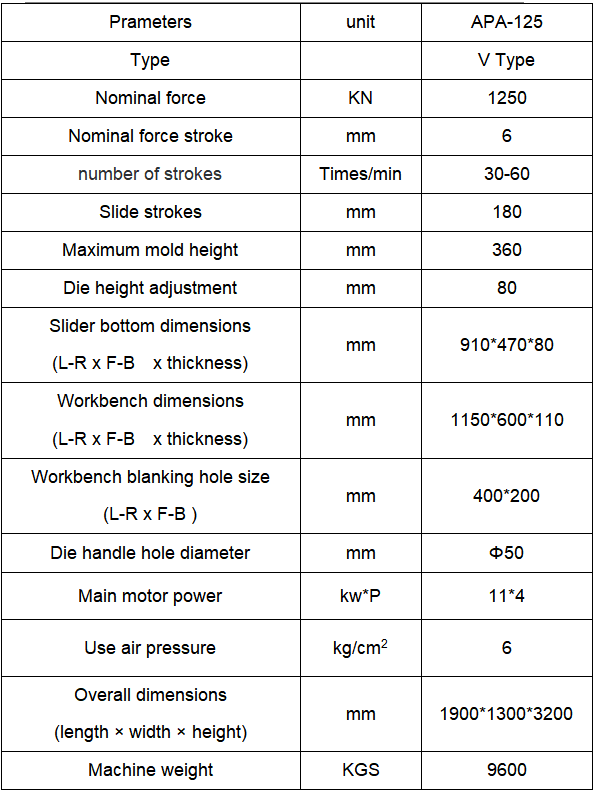

APA-125T High Precision pneumatic punch press

pneumatic press

The APA series pneumatic punch press is a vertical precision press with the following main features:

Core Functions

Pneumatic Drive: Utilizing compressed air as the power source, the cylinder propels the slide to achieve the punching action.

CNC/Manual Control: Select models support CNC operation with pre-set punching programs; traditional models use manual control of the slide stroke.

High Precision: Die adjustment accuracy reaches 0.1mm, making it suitable for precision metal parts processing.

Applications

Metal Processing: Suitable for stamping and forming metal materials such as aluminum profiles and plastic steel.

Mass Production: Supports batch sizes of one unit, making it suitable for small and medium-sized processing companies.

Typical Specifications

Tonnage: Available in various sizes, including 60, 80, and 110 tons.

Stroke: Slide stroke ranges from 120mm to 180mm.

Throat Depth: Select models feature a deep throat design up to 1500mm.

pneumatic punch press

Main Machine Tool Features:

1) Machine body: Made of Q235-B steel, welded from metallic yellow steel plates;

2) Crankshaft forged from 40Cr steel;

Sliders electrically adjusted by a disc motor with digital display for die height adjustment (manual adjustment for machines under 60T);

3) Sliders utilize rectangular hexahedral extended guide rails with alloy wear-resistant liners for high guiding precision;

4) Sliders’ vertical movement is assisted by two pneumatic cylinders, with the manipulators also driven by the cylinders;

5) Main bearings (Harbin Bearings);

6) Seals (SOG, NAK);

7) Cylinders (Ningbo Zhenhai Jingmao);

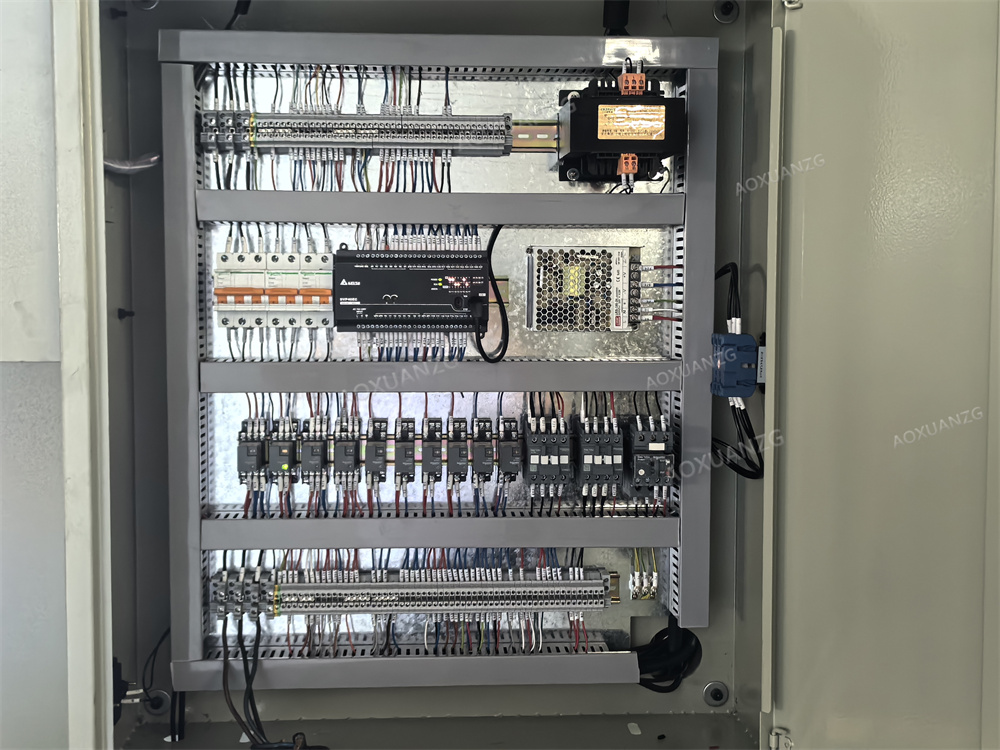

8) Main electrical components (Schneider);

9) Automatic refueling pump (Zhejiang Nanfang Pump Industry);

10) Dry clutch;

11) Motors from high-quality domestic brands;

12) PLC (Delta, Taiwan);

13) Standard optoelectronic protection (Genghao, Guangdong);

14) Standard hydraulic overload protection (Showa, Japan);

15) Standard sinusoidal frequency converter;

16) Standard control system (Delta);

17) Dual valves (Toyoshi, Japan).