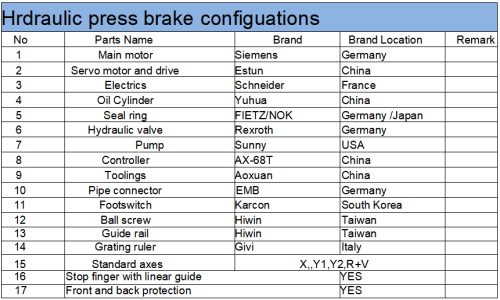

170T2500MM CNC Hydraulic press brake 4+1 axis with China AX-68T controller

$19,500.00 Original price was: $19,500.00.$18,800.00Current price is: $18,800.00.

1、Price content FOB Shanghaiprice , China

2、Valid price: within 30 days;

3、Payment method: When the product sales contract and technical agreement are signed, 30% of the total amount of the contract will be paid, and 70% of the total amount of the contract will be paid at the time of delivery by T/T or L/C.

4、Delivery period: 30 working days after receipt the deposit;

5、Packing: simple packaging, not recycling;

This CNC hydraulic press brake machine is advanced in technology and reliable in metal sheet bending performance. It is widely used in plane, automobile, trucks, shipbuilding, various fabrication industry with high production efficiency

.

Descrption of the CNC hydraulic press brake

1.The main oil cylinders on both sides are synchronized with German imported electro-hydraulic servo valve and Spanish company grating ruler to form a closed-loop control. The feedback is accurate and the slider is running accurately, so the bending precision and the sliderrepeatable positioning accuracy are high.

2.The V axis mechanically compensates. Solve the impact of the deformation of the slider during the bending process on the quality of the workpiece. The compensation amount is automatically adjusted by the CNC system, which is convenient and accurate.

3.The fuselage adopts the split steel plate welding structure. After tempering and vibration aging treatment, the distortion caused by welding stress and processing stress is eliminated, and the accuracy of the machine tool is maintained.

4.The fuselage adopts split assembly structure, which is convenient for transportation, convenient for processing, and can ensure the precision of the machine tool.

5.The important components such as the machine bodyand the slider are analyzed with ANSYS finite element analysis software to ensure the reliability of the machine tool.

6.The hydraulic system adopts the integrated control system imported from Germany, which reduces the installation of pipelines, improves the working stability of the machine tool, and has a beautiful and concise appearance.

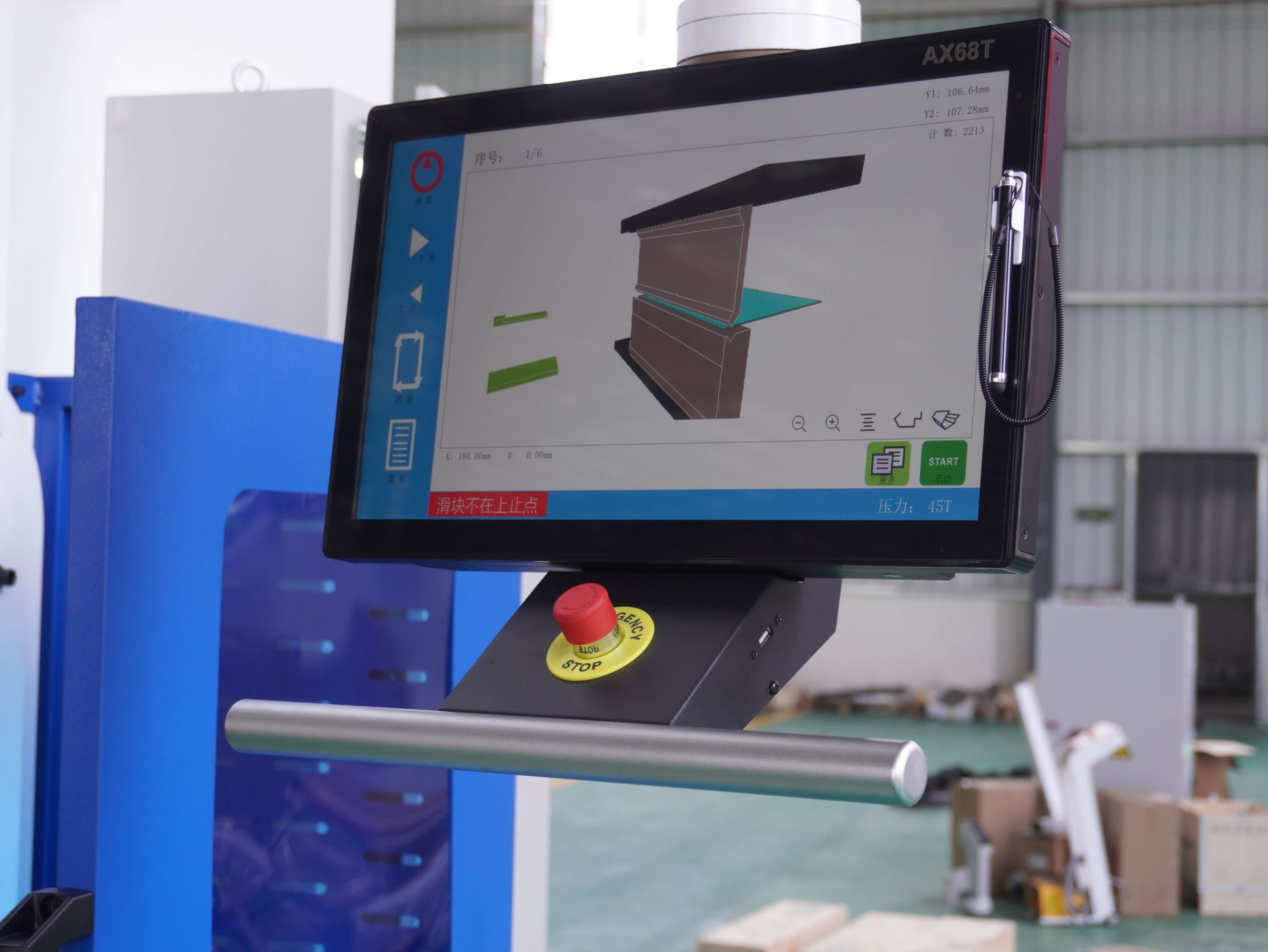

7.It can be divided into parts, can be assembled into a certain length according to the requirements of the workpiece to meet the processing needs of special parts. The upper die adopts safety ditch structure (European standard), and the lower die adopts modular structure to adapt to different parts. Need

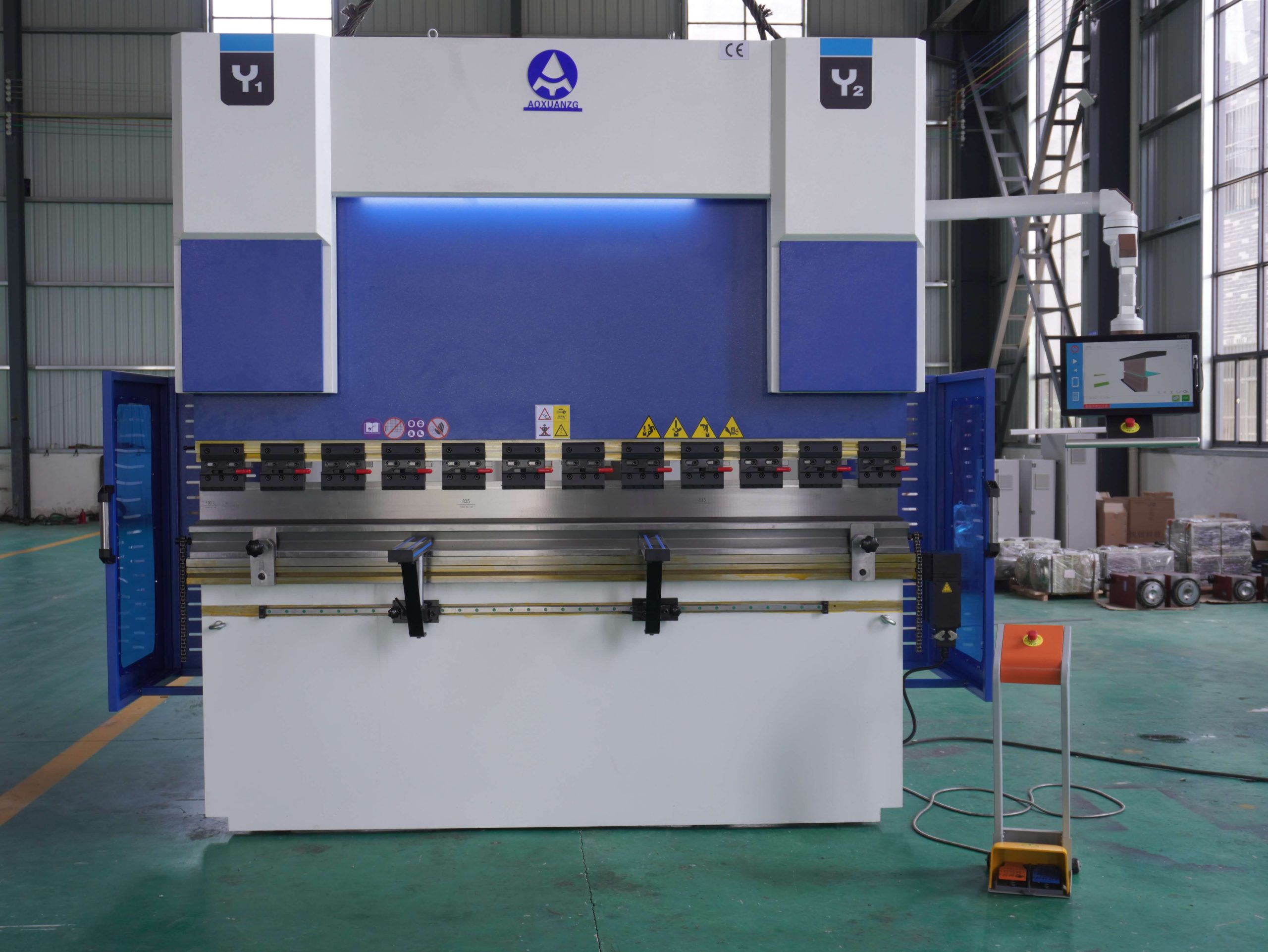

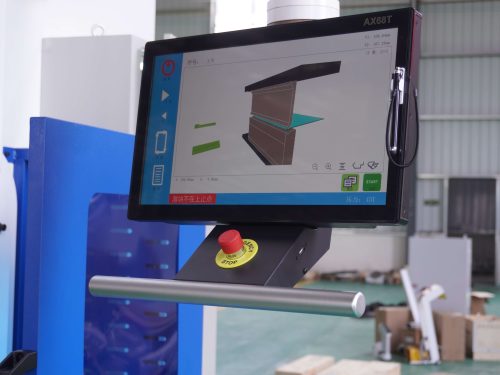

8.The CNC system uses the AX-68T

9.There are C-shaped plates on both sides of the fuselage, and the high-precision grating scale is installed on the C-shaped plate, so as to avoid the impact of deformation of the fuselage on the bending accuracy during bending.

10.The cylinders are processed by a professional manufacturer, sealed sets imported from Germany, imported from Germany, to overcome oil leakage.

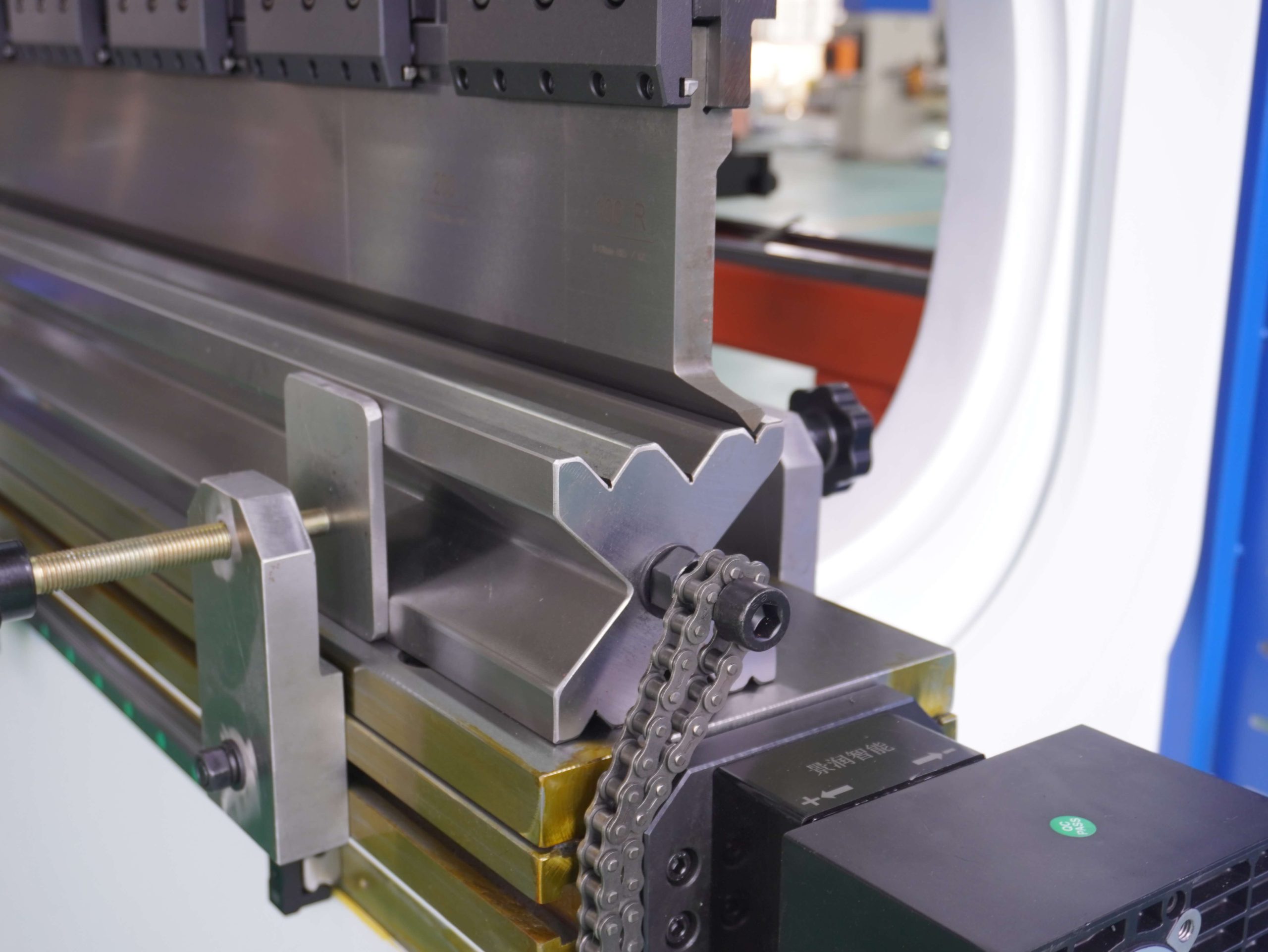

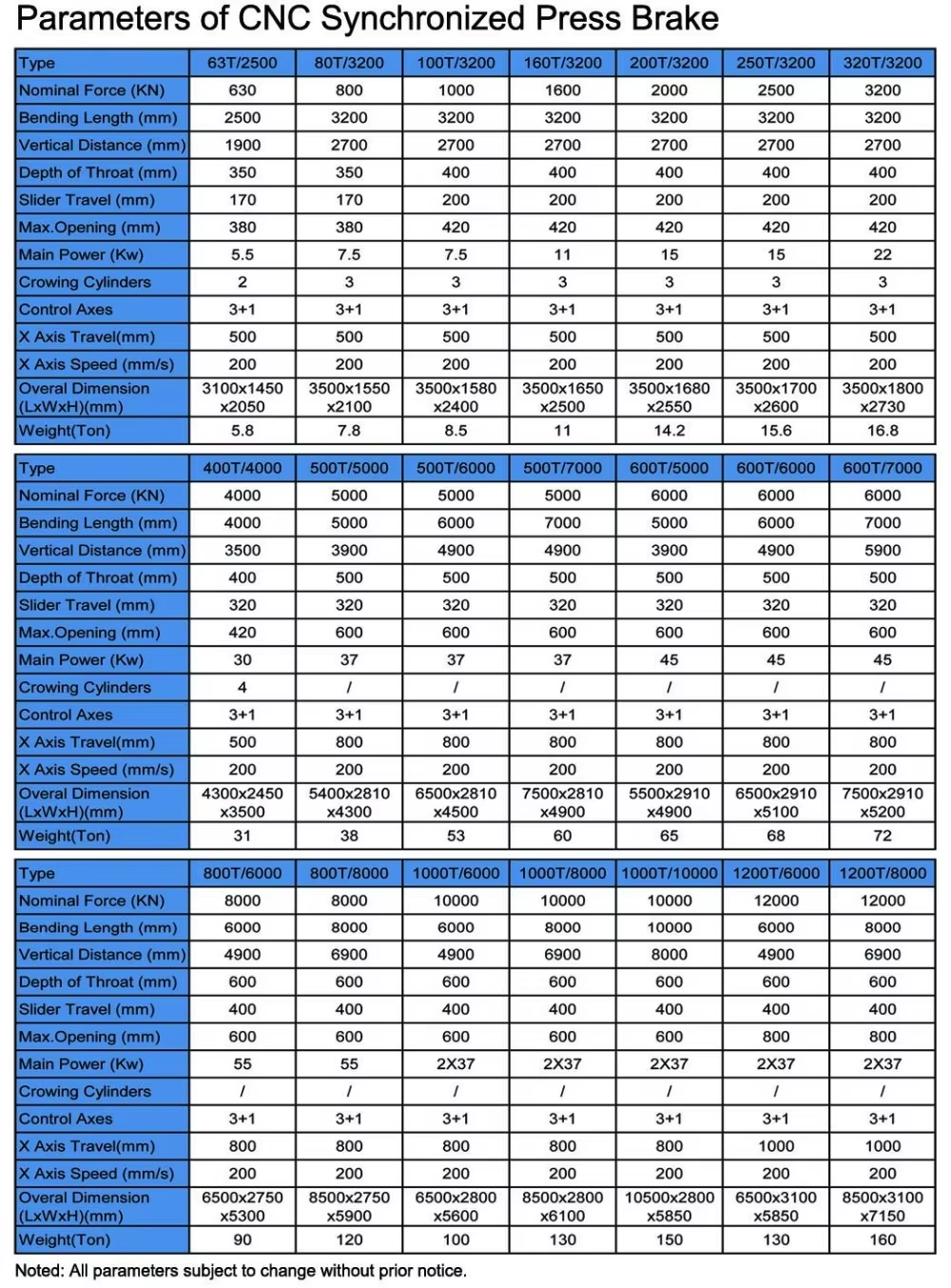

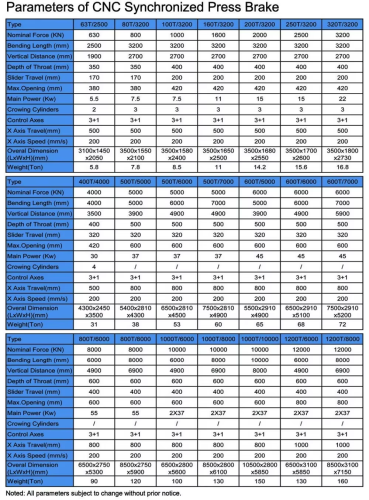

Machine configuations