45T Aluminum Foil Lunch Containers Semi Automatic Production Line With Pneumatic Punching Machine

$23,000.00

Product Details

Place of Origin: China

Brand Name: AOXUANZG

Certification: CE

Model Number: JF21-45

Payment & Shipping Terms

Minimum Order Quantity: 1 Set

Price: $23000-$50000/Set

Packaging Details: Standard export packing

Delivery time: 50-60 days

Payment Terms: L/C, T/T, Western Union, MoneyGram

Supply Ability: 50sets/Year

Product introduction:

The automatic aluminum foil lunch box production line is composed of an automatic feeding system with an oil tank, a high-precision pneumatic punch for aluminum foil lunch boxes, a high-precision multi-cavity mold (customized size according to customer requirements), a multi-track Automatic stacker, and a waste collection system. This production line has the advantages of high precision, high efficiency, low failure rate, and low waste rate. It is the most popular choice for small and medium-sized enterprises. It can produce various styles of aluminum foil lunch boxes, single-cavity, double-cavity, three-cavity, etc., and can also produce various aluminum foil containers such as coffee capsules.

Semi Automatic Components:

1. Automatic feeder.

2. 45/63/80T Aoxuanzg brand pneumatic press machine.

3. Single cavity / 2-cavity/3 cavity … Moulds.

4, Air compressor.

Advantages of this production line:

1. The feeder utilizes a servo system with automatic tension control, making it suitable for thinner materials.

2. The aluminum foil position is easily adjusted, reducing foil waste during adjustments.

3. The optimized stamping oil tank design significantly reduces fuel consumption to just 5 liters per ton of material (50 mic).

4. The stacker’s advanced parameter programming allows for easy adjustment, allowing one or half a person to operate and package the entire production line.

5. The PLC utilizes an intelligent modeling system, storing 50 sets of mold specifications and adjustment data.

6. Continuous upgrades in machine and mold technology have significantly reduced production noise.

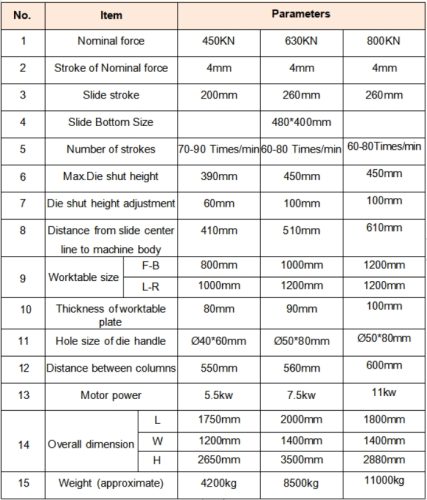

Parameter:

Molds:

1. The moulds that we design and produce are suitable for every kind of machine or press.

2. We produce mould with the best quality steel in China. And some main mould areas are made high-temperature heat treatment for proper hardness, which ensure moulds are in top quality and long life.

3. To meet customers’ different requirement, we design and manufacture the mould in several rims, such as G rim, L rim, H rim, and IVC etc.

4. We can design and produce the mould in multi-cavities, 1, 2, 3, 4 cavities or more. no matter it is one compartment container or multi-compartments container.

5. We can print your preferred logos upon request.

6. Scientific design make the Cutting Scrap Rate under good control.

7. Container shapes: square, rectangular, circular, oval, special shapes etc.

Packing:

1. Before packaged, the machines will be tested strictly to guarantee the stability and high accuracy.

2. After tested, the machines will be wrapped with plastic sheet ,

3,a,Small size : carefully packed in wooden cases ;

b,Big size: machine will be securely wired into the container by steel wire.

For more information, please contact me ~*^-^*