Good Price WC12 Sheet Metal 4 Roller Cnc Plate Bending Machine Roll Machine Professional Hydraulic Four Roller Bending Machine

1、Price content FOB Shanghaiprice , China

2、Valid price: within 30 days;

3、Payment method: When the product sales contract and technical agreement are signed, 30% of the total amount of the contract will be paid, and 70% of the total amount of the contract will be paid at the time of delivery by T/T or L/C.

4、Delivery period: 30 working days after receipt the deposit;

5、Packing: simple packaging, not recycling;

Good Price WC12 Sheet Metal 4 Roller Cnc Plate Bending Machine Roll Machine Professional Hydraulic Four Roller Bending Machine

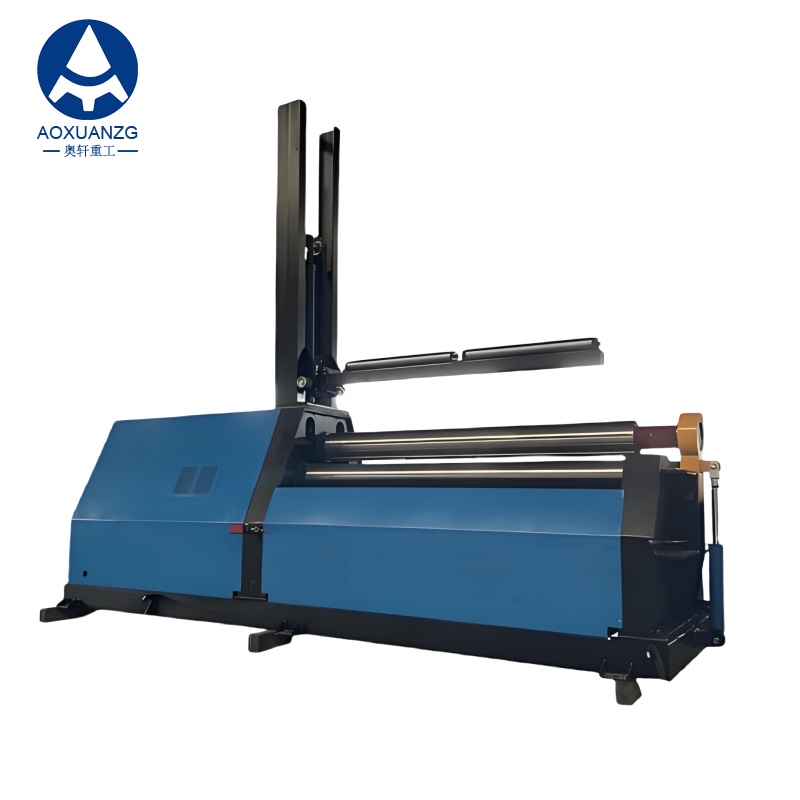

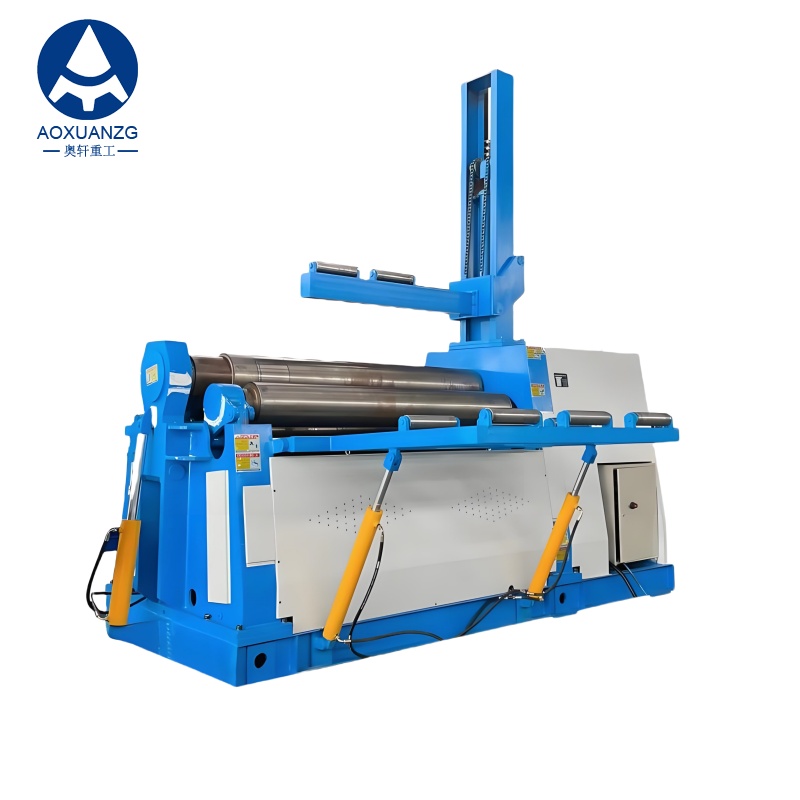

W12CNC Series Four-Roller Plate Rolling Machine

This machine is a four-roller plate rolling machine. Its operational principle involves the coordinated movement of four rollers:

-

Top Roller: Acts as the main drive, rotating to pull the plate through.

-

Lower Roller: Moves vertically to clamp the plate and generate the necessary feeding friction.

-

Side Rollers: Adjust up and down at an angle to the vertical axis, applying precise force to bend the plate to the desired curvature.

The significant advantage of this configuration is its ability to adjust the side rollers for both symmetric and asymmetric bending. This process minimizes the un-bent flat ends at the plate’s leading and trailing edges. Consequently, unlike three-roller machines, it eliminates the need for a separate pre-bending operation and dedicated equipment, while also providing a rough leveling function.

These efficiencies make it ideal for critical sectors like petroleum, chemical, boiler manufacturing, shipbuilding, hydroelectric power, metal structure, and machinery industries.

The advantages of four-roller bending machine

1. Hydraulic Drive System: High efficiency and energy saving, with a driving power consumption that is only 60% of traditional bending machines.

2. Permanent Lubrication: Bearings are lubricated for life, eliminating the need for refueling throughout their entire service period.

3. Adjustable Clamping Pressure: Prevents slippage effectively, resulting in a production efficiency that is 50% to 80% higher than that of three-roller machines.

4. High Forming Capacity: Capable of achieving a final cylinder diameter as small as 1.1 times the diameter of the top roller.

Key Features of Our Four-Roller Plate Rolling Machine

-

CNC Integration: Equipped with a precise CNC control system for automated operation and repeatable results.

-

Integrated Leveling: Capable of rough leveling the plate prior to rolling, streamlining the process.

-

Single-Pass Forming: Enables the completion of a cylindrical shape, including pre-bending, in a single setup, eliminating secondary operations.

-

Enhanced Cone Rolling: The independent control of rollers provides greater convenience and precision for forming large conical sections.

-

Simplified Correction: Allows for easy correction of misaligned edges during the rolling process, improving efficiency.

-

Arc-Swing Mechanism: The side rollers pivot on an arc, creating a leveraged force that maximizes bending power with minimal hydraulic effort.

-

Proportional Synchronization: The two side rollers are synchronized via proportional valves, ensuring precise and balanced movement for superior roundness.

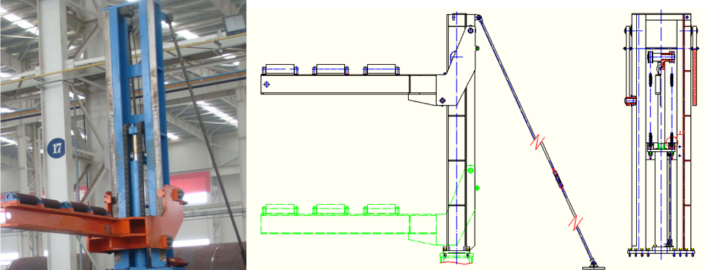

A. Top Supporting Device (Optional)

-

Function: Provides internal support during automated rolling of cylinders to prevent sagging and control deformation.

-

Operation: Hydraulically-driven, adjustable frame moves synchronously to support from inside the workpiece and retracts to clear the seam.

-

Benefit: Improves quality, efficiency, and reduces manual labor.

-

Installation: Requires customer to pre-embed foundation anchors for two ground support points.

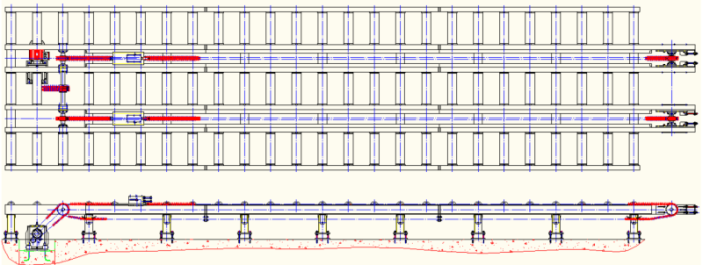

B. Side Supporting Device (Side Supports)

-

Function: To support large-diameter cylinders during rolling, preventing sagging and ensuring accuracy.

-

Design: Each side features multiple rows of rollers.

-

Operation: Each support can be split into two sections for independent operation, providing better conformity.

-

Multi-Purpose: When lowered, the supports can act as rollers.

-

Additional Feature: The infeed-side support is equipped with an axial hydraulic push rod

-

C. Feeding Platform

The feeding system features a conveying roller track to streamline material handling. This system uses rollers, motors, reducers, and hydraulic cylinders to support the steel plate and feed it directly into the plate rolling machine.

An automatic centering device acts as a rapid long-side alignment system. Two of these units, installed at the front and rear of the track, ensure precise positioning. They boast a compact structure, fast response, high accuracy, reliable operation, and strong versatility. Each device includes feeding rollers, a power unit, guide rails, and mounting brackets.

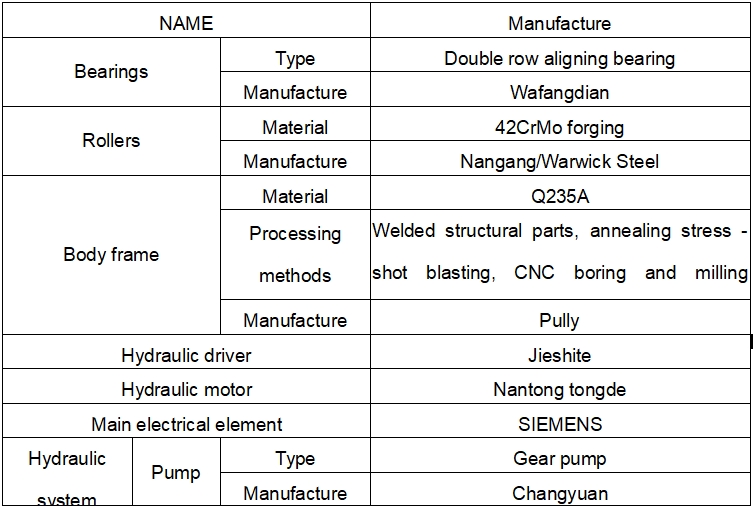

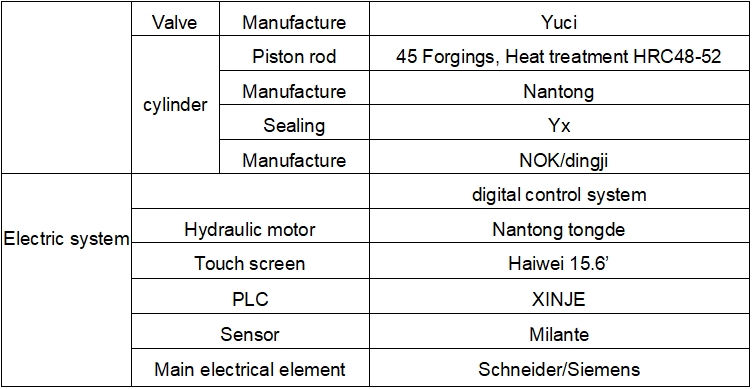

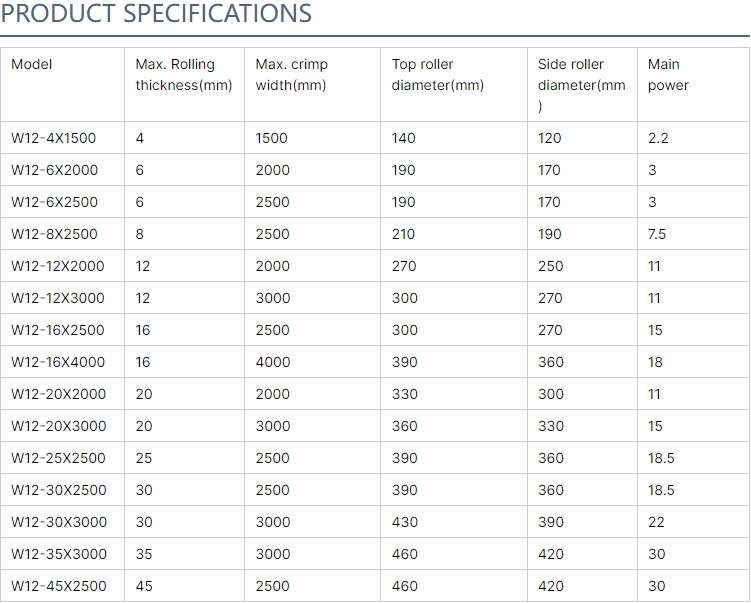

Machine Parametetrs

Control System Technical Features

-

Core Architecture: Comprises a high-reliability industrial PLC and rotary encoders, forming a high-performance, stable control system.

-

CNC Capabilities: Provides real-time monitoring, seamless data transfer, and a power-off memory function to retain settings.

-

Precision Synchronization: The PLC automatically controls the lower and side rollers, guaranteeing a synchronization precision of ±0.15 mm.

-

Human-Machine Interface (HMI): A programmable display shows real-time roller positions and allows for parameter setting.

-

High-Accuracy Sensing: Displacement transducers offer a resolution of 0.10 mm and a display accuracy of ±0.10 mm.

-

Smart Functionality: Equipped with an automatic self-diagnostic and judgment function.

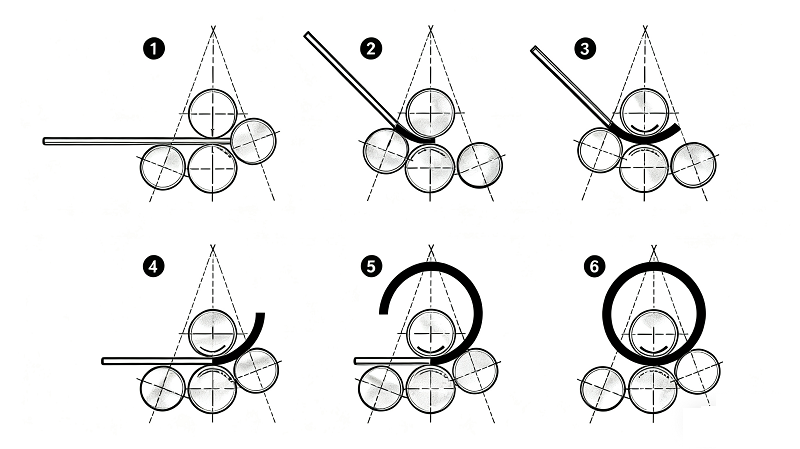

Plate bending process

-

Standard Plate Rolling Procedure

-

Position and Clamp: Align the leading edge of the plate with the front main roller. Raise the lower roller to clamp the plate securely.

-

Set for Pre-bending: Retract the plate so its leading edge is near the nip point of the upper and lower rolls. Lower the front side roller and raise the rear side roller to their pre-bending positions.

-

Pre-bend the Edge: Drive the main rolls to rotate the plate. Pre-bend the leading edge to the required curvature.

-

Set for Rolling: Lower the rear side roller and raise the front side roller to their starting positions for the full rolling cycle.

-

Roll the Plate: Drive the main rolls to continuously roll the plate into a cylinder.

-

Finish the Roll: Once the trailing edge of the plate approaches the nip point, stop rotation to complete the rolling process.

-

Machine configuations