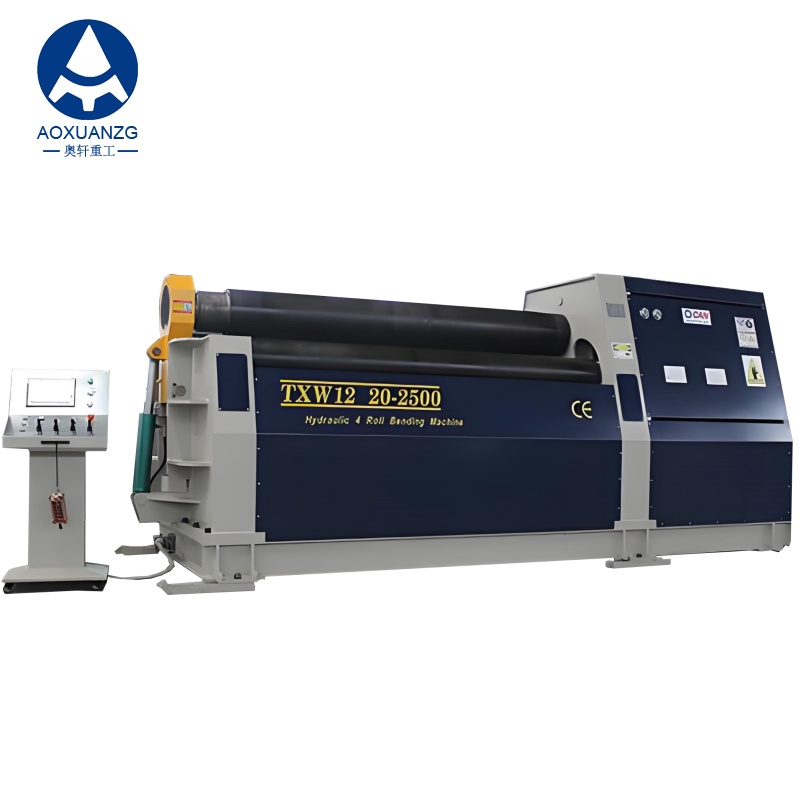

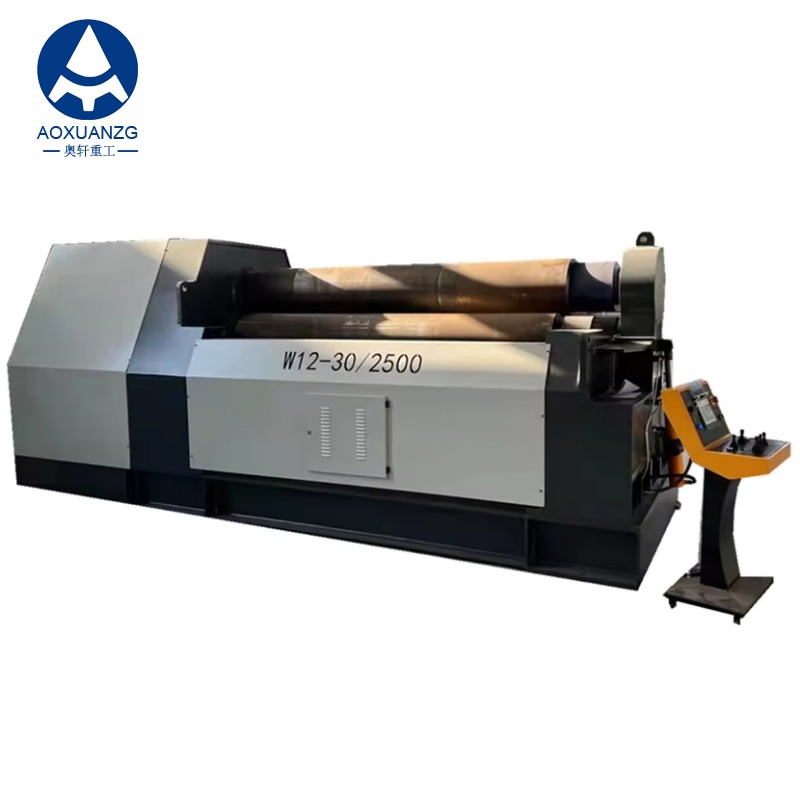

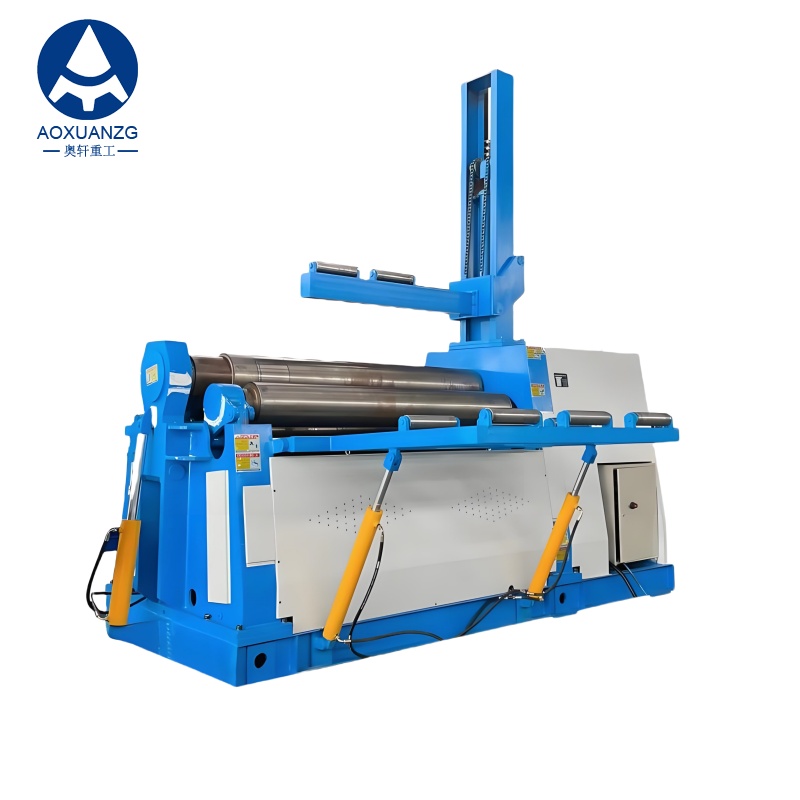

CNC-Blechwalzmaschine mit vier Walzen, Modell 30 x 3000 mm

1. Preisinhalt FOB Shanghai-Preis, China

2. Gültiger Preis: innerhalb von 30 Tagen;

3. Zahlungsmethode: Wenn der Produktkaufvertrag und die technische Vereinbarung unterzeichnet sind, werden 30% des Gesamtbetrags des Vertrags bezahlt, und 70% des Gesamtbetrags des Vertrags werden zum Zeitpunkt der Lieferung per T/T oder L/C bezahlt.

4. Lieferzeit: 30 Werktage nach Erhalt der Anzahlung;

5. Verpackung: einfache Verpackung, kein Recycling;

CNC-Blechwalzmaschine mit vier Walzen, Modell 30 x 3000 mm

Vier-Rollen-Blechwalzmaschine der W12CNC-Serie

Diese Maschine ist mit fortschrittlicher deutscher Technologie ausgestattet.

>>Es verwendet eine SPS-programmierbare digitale Steuerung.

>Es verfügt über einen vollhydraulischen Antrieb.

>Es automatisiert den Vier-Walzen-CNC-Blechwalzprozess.

Die Maschine verfügt über eine fortschrittliche Struktur.

Es bietet überlegene Leistung und hohe Präzision.

Es arbeitet mit hoher Effizienz und ist sehr komfortabel.

Seine Technologie ist im Vergleich zu ähnlichen Produkten weltweit führend.

Der Bediener fährt die untere Rolle nach oben.

Es klemmt die Stahlplatte gerade.

Die obere Walze bleibt in einer festen Position.

Zwei seitliche Rollen bewegen sich zusätzlich gerade nach oben.

Dadurch wird der Krümmungsradius der Trommel angepasst.

Es führt das Blech nur einmal zu.

Damit ist das Vorbiegen und Rollen ohne Drehen abgeschlossen.

Sie können den automatischen Modus zum Stapelrollen verwenden.

Dadurch wird eine gleichmäßige Formgebung des Werkstücks gewährleistet.

Es ist ideal zum Rollen verschiedener Formen.

Hierzu zählen zylindrische, gekrümmte und konische Werkstücke.

Es rollt auch rechteckige und andere Formen.

Es ist das bevorzugte Modell für viele Branchen.

Zu diesen Branchen zählen die Metallurgie und die Baustoffindustrie.

Es dient der Erdöl-, Chemie- und Wasserwirtschaft.

Es dient auch der Stromversorgung, der Brückenversorgung und der Kohleversorgung.

Weitere Industriezweige sind der Bergbau, der Schiffsbau und die Kesselindustrie.

Es dient auch der Luftfahrt, dem Umweltbereich und der Metallkonstruktion.

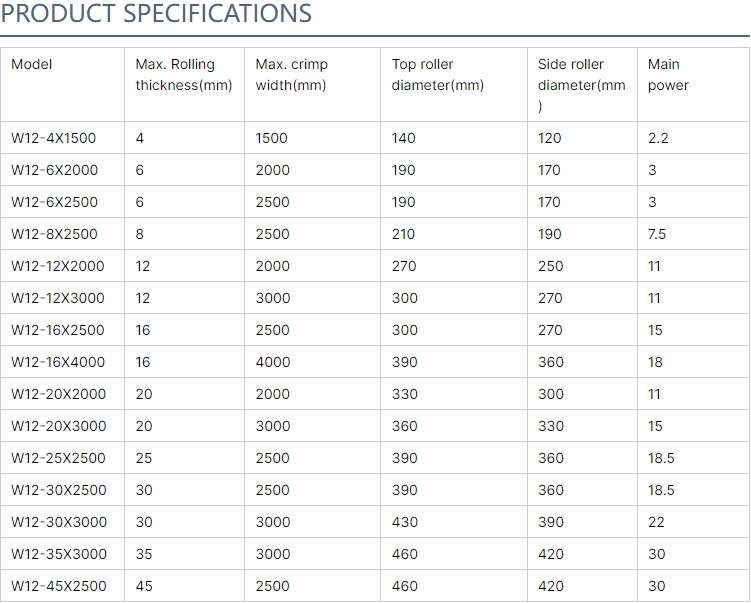

Maschinenparameter

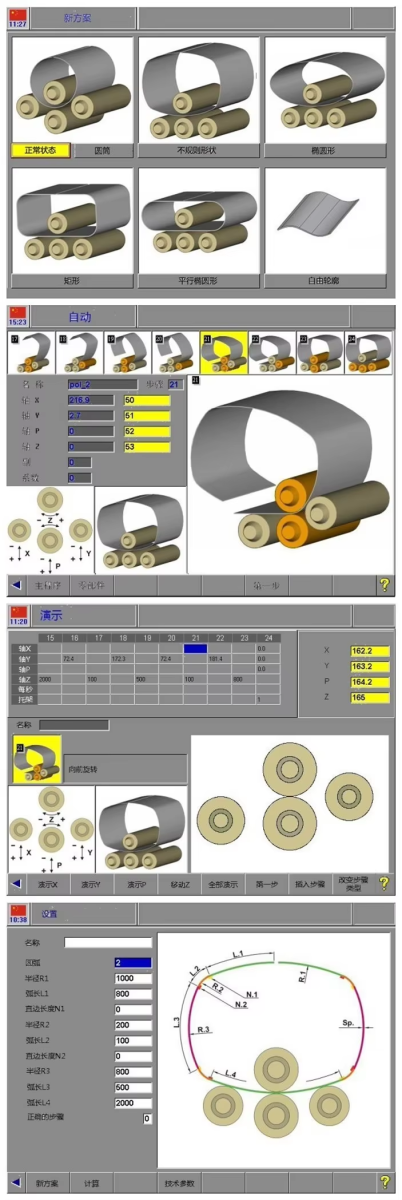

Das System verwendet einen Rotationsgeber, der mit einem hochzuverlässigen Industrie-Controller kombiniert ist, wodurch ein Steuerungssystem mit stabiler Leistung entsteht.

Das CNC-System ermöglicht eine Echtzeitüberwachung während des Walzprozesses. Zusätzlich gewährleistet es einen reibungslosen Datentransfer. Darüber hinaus ist es mit einer Power-Off-Memory-Funktion ausgestattet.

Die SPS der Industriesteuerung prüft die untere Position und die beiden Enden der Seitenrollenposition automatisch und steuert sie, um eine Synchronisierungsgenauigkeit von ±0,15 mm sicherzustellen

Die programmierbare Anzeige zeigt die Position der unteren Walze und der beiden Enden der Seitenwalzen in Echtzeit an und kann eingestellt werden.

Die Auflösung des Wegaufnehmers beträgt 0,10 mm, die Anzeigegenauigkeit beträgt ±0,10 mm

Automatische Selbstbeurteilungsfunktion

Plattenbiegeprozess

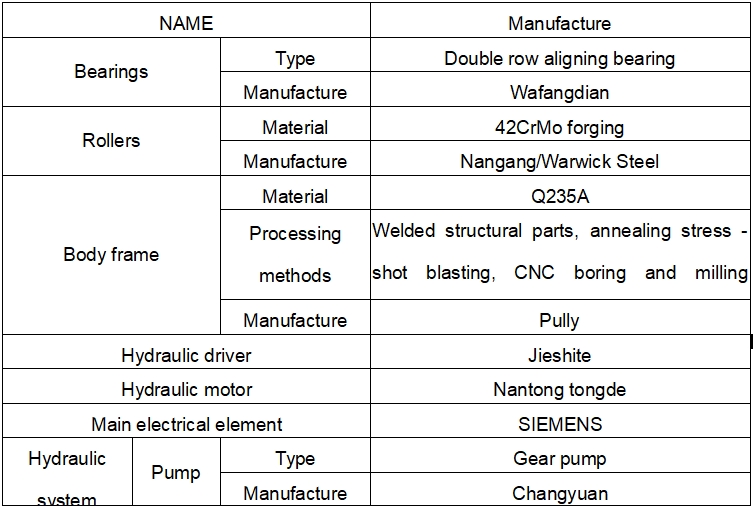

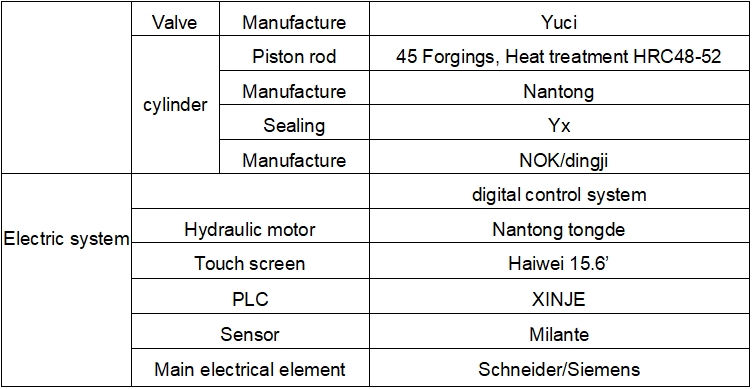

Maschinenkonfigurationen