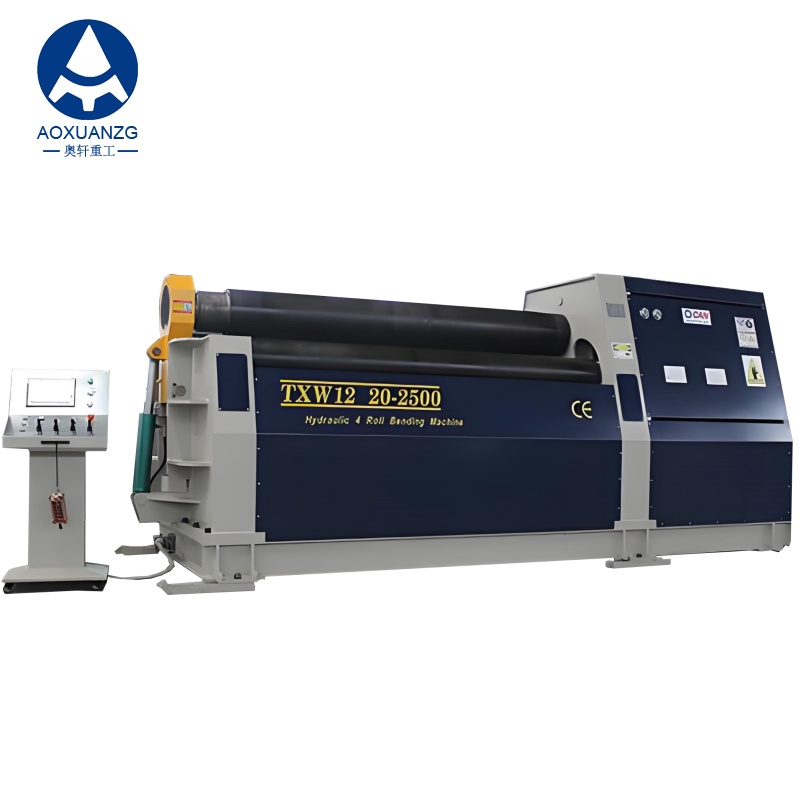

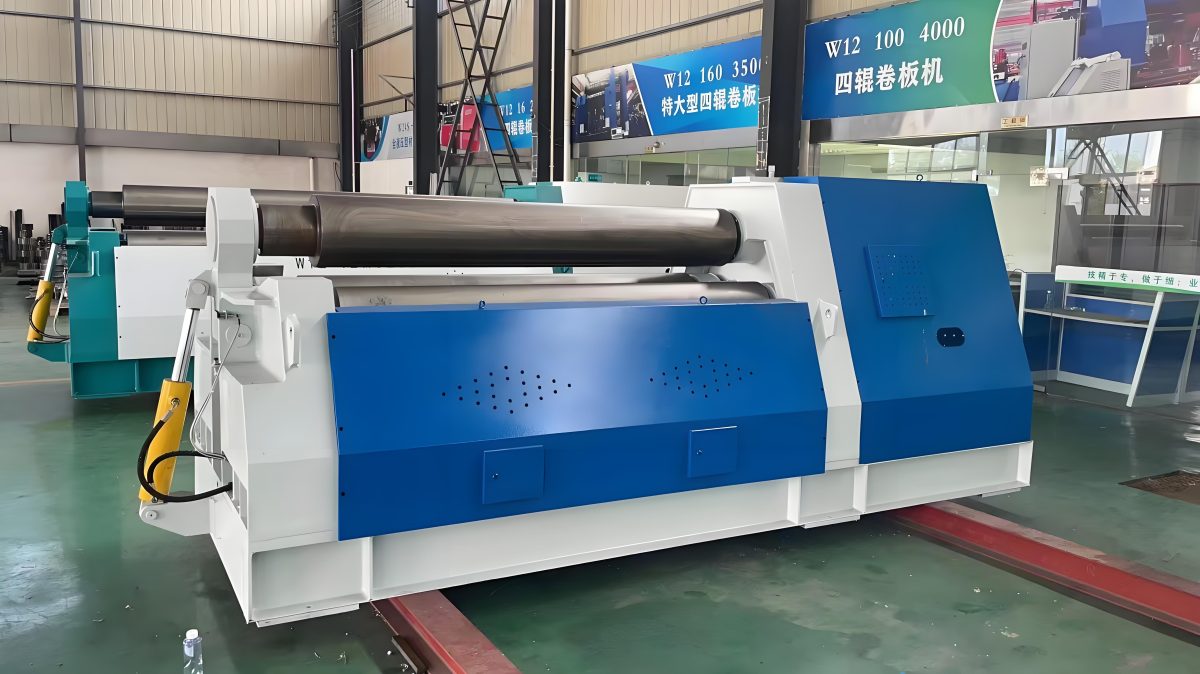

Гидравлический гибочный станок с ЧПУ W12-10*3000, автоматическая четырехвалковая вальцовка листового металла для шестерней из нержавеющей стали с ПЛК-ядр

1. Цена указана на условиях поставки FOB в Шанхае, Китай.

2. Цена действительна: в течение 30 дней;

3. Способ оплаты: После подписания договора купли-продажи продукции и технического соглашения будет выплачено 30% от общей суммы договора, а 70% от общей суммы договора будут выплачены в момент поставки посредством банковского перевода или аккредитива.

4. Срок поставки: 30 рабочих дней после получения депозита;

5. Упаковка: простая упаковка, не подлежащая переработке;

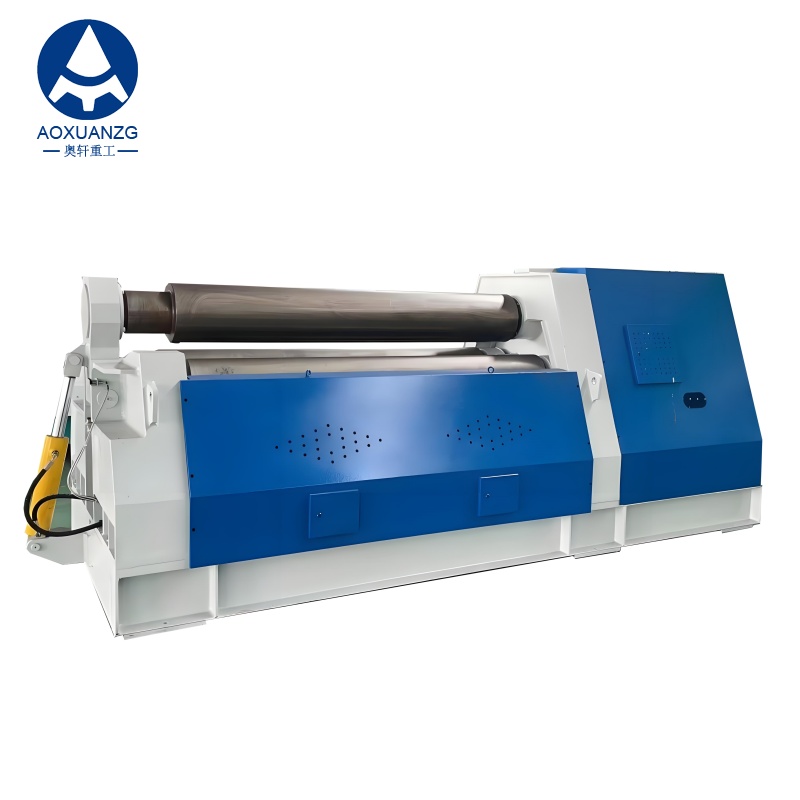

Гидравлический гибочный станок с ЧПУ W12-10*3000 с четырьмя валками для листовой стали и нержавеющей стали

Четырехвалковый листопрокатный станок серии W12CNC

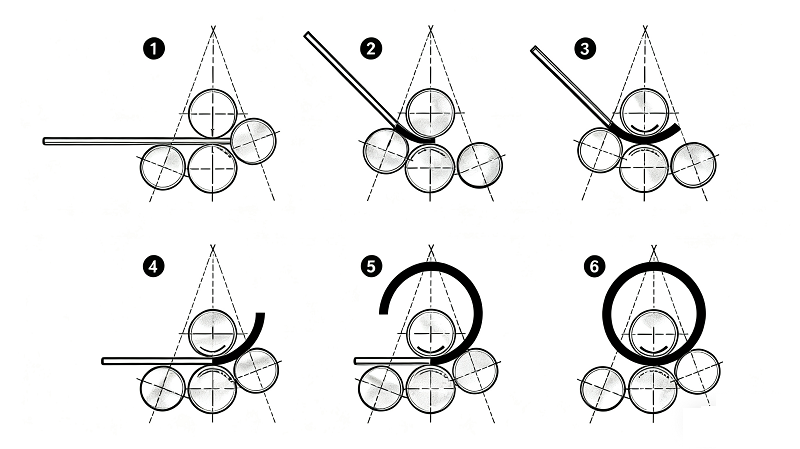

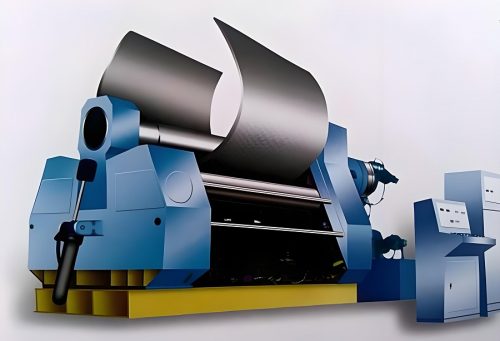

Данная машина представляет собой четырёхвалковую листопрокатную машину. Принцип её работы основан на согласованном движении четырёх валков:

-

Верхний ролик: Выступает в роли главного привода, вращаясь и протягивая пластину.

-

Нижний ролик: Перемещается вертикально, чтобы зажать пластину и создать необходимое трение подачи.

-

Боковые ролики: Регулируйте вверх и вниз под углом к вертикальной оси, прикладывая точное усилие, чтобы согнуть пластину до нужной кривизны.

Существенным преимуществом данной конфигурации является возможность регулировки боковых валков как для симметричной, так и для асимметричной гибки. Это минимизирует количество несогнутых плоских торцов на передней и задней кромках листа. Следовательно, в отличие от трёхвалковых машин, исключается необходимость в отдельной операции предварительной гибки и специальном оборудовании, а также обеспечивается функция грубой правки.

Благодаря этим показателям эффективность данной машины широко используется в важнейших отраслях, включая нефтяную, химическую, котлостроение и производство сосудов высокого давления, судостроение, гидроэнергетику, металлоконструкции и машиностроение.

Процесс гибки пластин

-

Стандартная процедура прокатки листов

-

Положение и зажим: Совместите передний край пластины с передним основным роликом. Поднимите нижний ролик, чтобы надёжно зафиксировать пластину.

-

Набор для предварительной гибки: Отведите лист так, чтобы его передний край оказался рядом с точкой защемления верхнего и нижнего валков. Опустите передний валок и поднимите задний валок в положение, соответствующее предварительной гибке.

-

Предварительно согните край: Приведите в движение основные валки, чтобы вращать пластину. Предварительно согните переднюю кромку до необходимой кривизны.

-

Набор для прокатки: Опустите задний боковой ролик и поднимите передний боковой ролик в исходное положение для полного цикла прокатки.

-

Раскатываем тарелку: Приводите в движение основные валки, чтобы непрерывно скручивать пластину в цилиндр.

-

Закончите ролл: Как только задняя кромка пластины приблизится к точке защемления, прекратите вращение, чтобы завершить процесс прокатки.

-

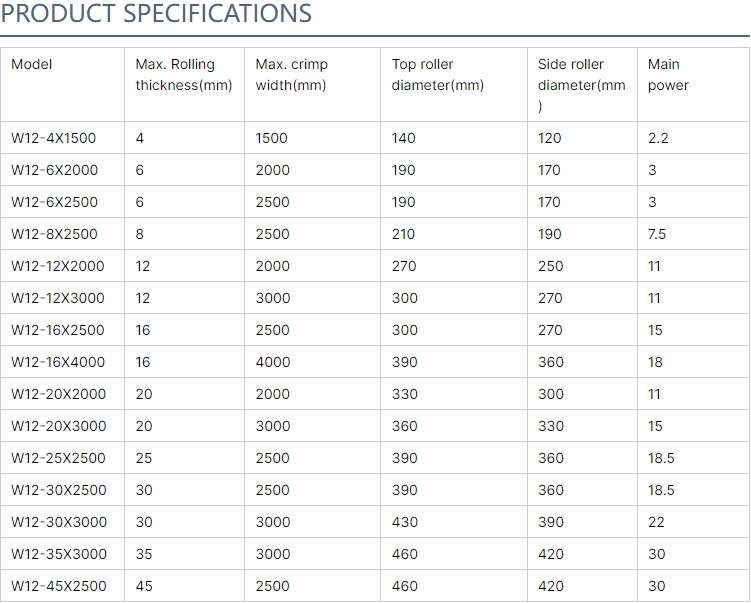

Параметры машины

Технические характеристики системы управления

-

Основная архитектура: Состоит из высоконадежного промышленного ПЛК и вращающихся энкодеров, образующих высокопроизводительную и стабильную систему управления.

-

Возможности ЧПУ: Обеспечивает мониторинг в режиме реального времени, бесперебойную передачу данных и функцию памяти при отключении питания для сохранения настроек.

-

Точная синхронизация: ПЛК автоматически управляет нижними и боковыми роликами, гарантируя точность синхронизации ±0,15 мм.

-

Человеко-машинный интерфейс (HMI): Программируемый дисплей отображает положение роликов в реальном времени и позволяет настраивать параметры.

-

Высокоточное зондирование: Датчики смещения обеспечивают разрешение 0,10 мм и точность отображения ±0,10 мм.

-

Умная функциональность: Оснащен функцией автоматической самодиагностики и оценки.

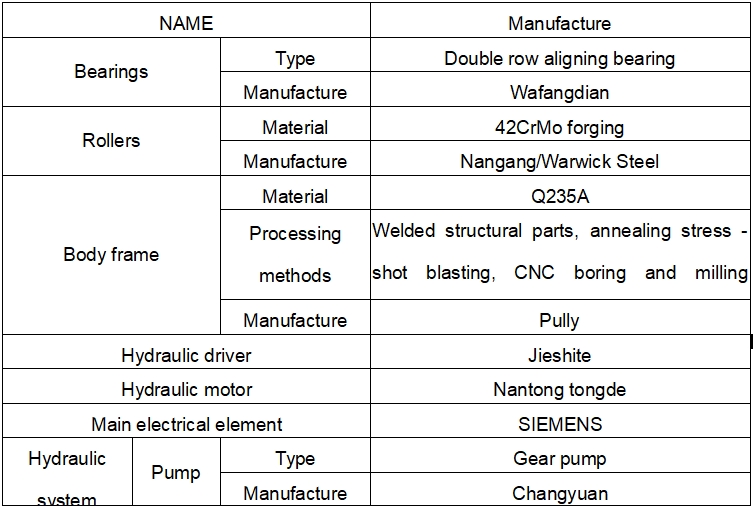

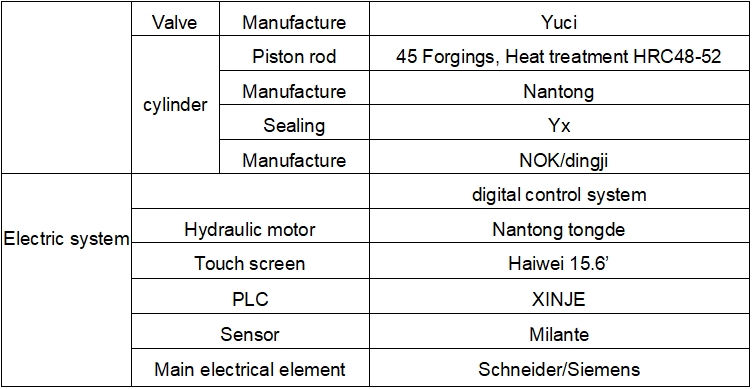

Конфигурации гидравлической четырехвалковой прокатной машины