The AX-68T CNC system is a press brake CNC system independently developed in China. It is a control system designed specifically for high-precision electro-hydraulic press brakes, combining the technical advantages of current domestic CNC systems with the development trend of intelligentization. The following is a detailed introduction:

I. Core Functions and Technical Parameters

Hardware Compatibility

Supports equipment with nominal pressures of 800-10,000 kN, with worktable lengths ranging from 3,000-6,000 mm and throat depths of 250-400 mm.

Utilizing variable frequency motor control (7.5-60kW), the machine achieves travel speeds of 15-30 strokes per minute, meeting requirements for processing high-strength materials such as stainless steel and aluminum alloys.

Control Performance

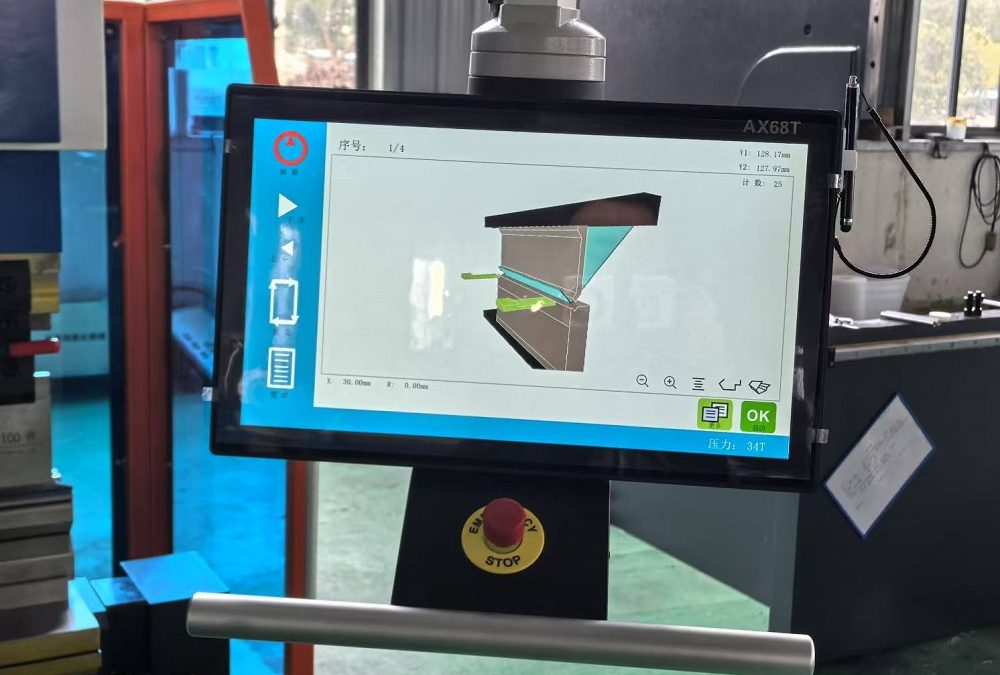

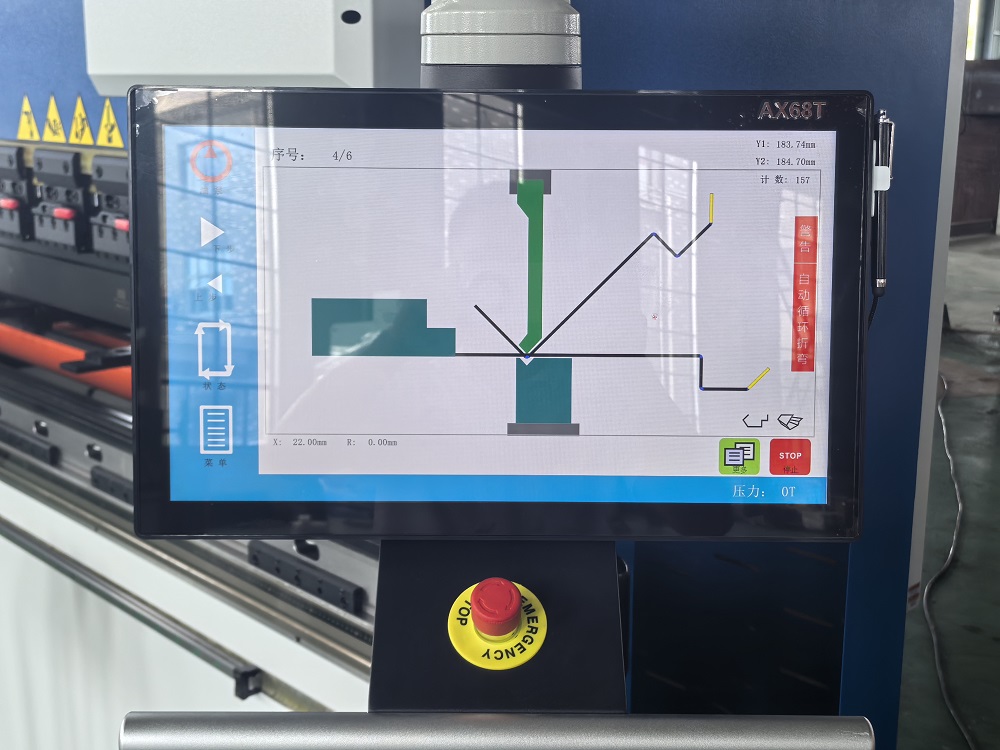

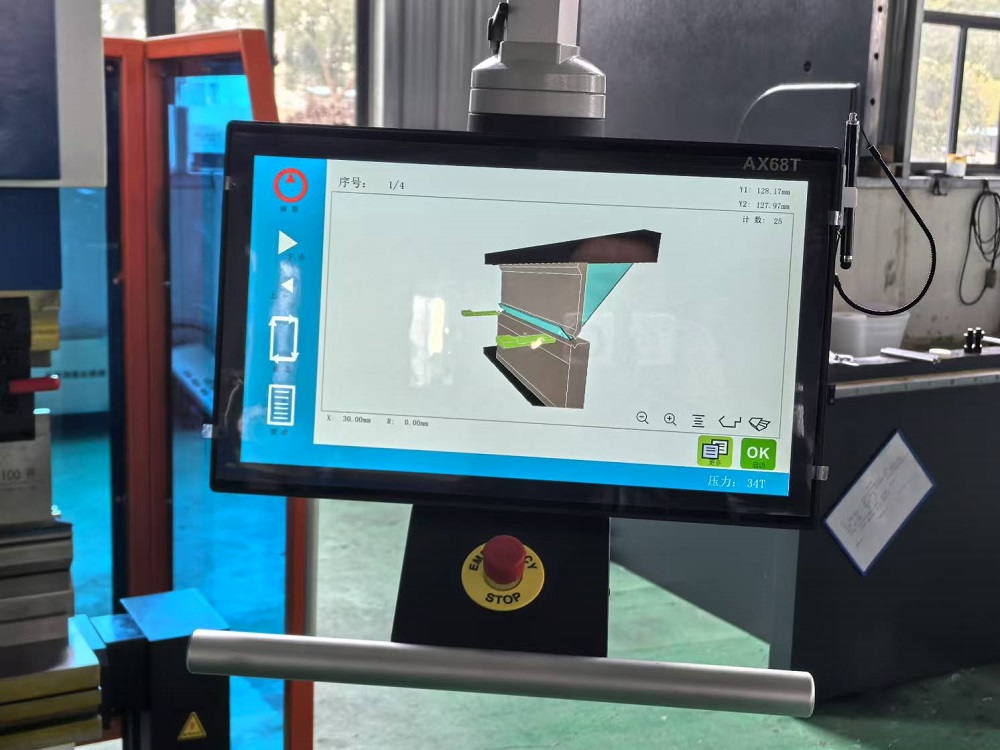

Integrated 3D programming interface supports one-click input of sheet thickness, material, and mold parameters, automatically calculating the bending sequence and compensation amount.

Features angle-pressure linkage control and real-time deflection compensation, achieving repeatability of ±0.02 mm.

II. Operation and Intelligent Features

Human-Machine Interaction Design

Equipped with a 10.1-inch industrial-grade touchscreen, Supports graphical programming and multi-language switching.

Provides inching, single-step, and continuous machining modes, compatible with G-code import and cloud-based process library access.

Intelligent expansion capabilities.

Reserved IoT interfaces allow connection to vibration sensors, laser rangefinders, and other devices for condition monitoring.

The software supports OTA remote upgrades, with AI process optimization modules to be expanded in the future.

III. Application Scenarios and Compatibility.

Suitable for complex curved surface machining in automotive sheet metal, elevator cabins, cabinets, and other applications, supporting 8-axis linkage (Y1/Y2/X1/X2.Z1/Z2 ).

The system is compatible with domestic hydraulic valve manifolds and imported servo cylinders, and is CE-certified for export.

This system is expected to perform well in the domestic high-end press brake market after 2024. Its technological approach differentiates it from specialized press brake systems from European and American brands such as Delem and Cybtouch.